At Dynamic Balancing Technologies, we believe in delivering more than just repair services. We offer precision-engineered dynamic balancing methods designed to optimize the performance of your rotating machinery. Based in Romeo, Michigan and serving the greater Detroit area, our experienced team specializes in diagnosing and correcting balance-related issues that can lead to costly downtime, component failure, and reduced equipment efficiency. With over three decades of experience in mechanical engineering and vibration diagnostics, we’re here to help industries across Detroit maintain the smooth, reliable operation their equipment depends on.

Why Dynamic Balancing Matters for Detroit’s Industrial Operations

Effective dynamic balancing is essential for any operation that relies on high-speed rotating equipment. As mechanical engineers, we’ve seen firsthand how even minor issues with mass distribution can cause significant operational disruptions. Detroit is home to a diverse range of industrial applications, including automotive and aerospace manufacturing, HVAC, energy production, and food processing. These sectors rely on dependable rotating equipment, which means any imbalance can result in decreased efficiency, increased noise levels, component wear, and, ultimately, system failure. By implementing advanced dynamic balancing techniques, we help Detroit businesses maintain vibration-free operations, reduce energy consumption, and avoid unplanned maintenance costs.

Dynamic Balancing Technologies – Your Detroit-Based Partner for Vibration Solutions

Dynamic Balancing Technologies isn’t just a service provider—we’re your maintenance partner. Our facility is equipped with the tools, expertise, and technical background needed to deliver exceptional dynamic balancing results. As a certified mechanical engineer and industrial equipment supplier, our team understands the intricacies of rotating machines. We serve a broad range of clients throughout Detroit and the Midwest, including Michigan, Indiana, Illinois, and Ohio. Whether you operate a manufacturing facility, a commercial HVAC system, or a high-precision CNC shop, we offer solutions tailored to your specific industry and equipment needs.

Precision Dynamic Balancing for Rotating Equipment in Detroit

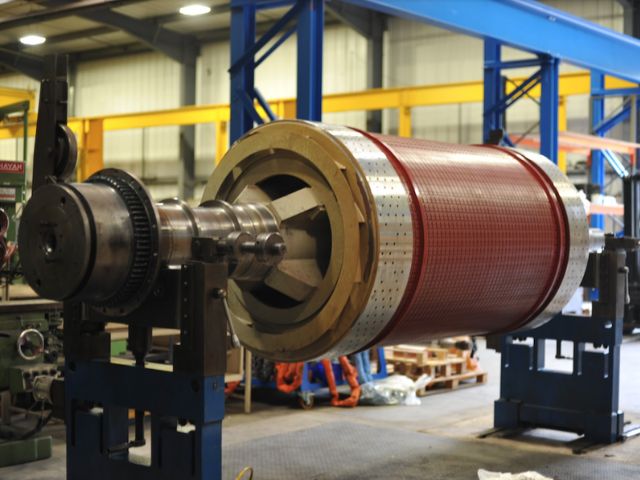

Dynamic balancing is the process of rotating an object to detect and correct imbalance by adjusting its mass. In practical terms, this means we measure vibration levels on your equipment and apply corrections, such as adding or removing weight, to restore the center of mass in line with the actual axis of rotation. We utilize ISO 1940 standards to determine the correct balance tolerances, ensuring your equipment operates with minimal vibration. This service is significant for components such as rotors, impellers, motors, shafts, fans, and others that rotate at high speeds. When balanced correctly, these components operate more quietly, reduce wear on bearings and couplings, and require less energy to run.

Static Balancing Services for Stationary Equipment

While dynamic balancing is crucial for moving components, static balancing plays an equally important role in addressing imbalances in stationary or slow-speed equipment. At Dynamic Balancing Technologies, we provide static balancing services that specialize in correcting single-plane imbalances. When a part such as a flywheel or pulley consistently rolls to the same heavy side, we know static balancing is necessary. By redistributing mass across a single axis, we eliminate the causes of vibration before they manifest during operation. This helps ensure greater machine stability, particularly in applications that don’t require high-speed rotation but still demand precision.

On-Site Field Balancing for Industrial Machinery in Detroit, MI

Transporting large equipment to a shop for balancing isn’t always feasible. That’s why we provide in-field dynamic balancing services throughout the Detroit area. Our technicians arrive equipped with portable balancing instruments, which enable us to perform real-time diagnostics and corrections on-site. Whether you operate pumps, HVAC systems, conveyors, or turbines, we can balance your machinery without requiring disassembly. This approach significantly reduces downtime, allowing you to resume operations quickly and efficiently. We serve factories, hospitals, data centers, and energy plants that can’t afford to halt production or services, offering responsive and accurate field balancing that meets your unique needs.

Diagnostic Vibration Analysis and Machinery Health Monitoring

Identifying a balance issue starts with data. Our vibration analysis services are designed to detect early warning signs of mechanical issues before they evolve into costly repairs. We analyze waveform data, frequency spectra, velocity measurements, and acceleration patterns to determine the source of vibration. Whether it’s imbalance, misalignment, bearing failure, or looseness, our equipment enables us to diagnose the problem accurately. We integrate these diagnostics into your predictive maintenance programs so your team has the insight needed to make informed decisions. Our detailed reports outline the problem, recommend corrective actions, and provide before-and-after data to demonstrate measurable improvement.

Laser Shaft Alignment for High-Speed and Interconnected Equipment

In many industrial systems, rotating machinery is connected through shafts that transfer power between components. If those shafts are misaligned—even by fractions of a millimeter—they can cause increased friction, heat buildup, bearing stress, and eventual system breakdown. At Dynamic Balancing Technologies, we use advanced laser alignment tools to ensure your machinery is aligned with precision. Our shaft alignment services are ideal for compressors, pumps, fans, blowers, and gearboxes. When properly aligned, these components last longer, operate more efficiently, and experience fewer breakdowns. Especially in fast-paced industries across Detroit, proper alignment translates to long-term savings.

Industrial Fan, Blower, and Motor Balancing in Detroit

Fans and motors are essential in industries where ventilation, airflow, and power transmission are vital. However, they are also prone to imbalance due to debris buildup, wear, or installation errors. We offer fan and blower balancing services that restore the efficiency of your HVAC, manufacturing, and utility systems. Our technicians balance axial and centrifugal fans, electric motors, and motor shafts to minimize energy usage, reduce noise, and prevent vibration-related damage. This service is crucial in Detroit’s commercial and industrial buildings, where maintaining consistent airflow and ensuring equipment longevity are top priorities.

CNC and Spindle Balancing for Precision Manufacturing

Modern manufacturing depends heavily on high-speed CNC machines and spindle tooling. These machines are expected to deliver accurate cuts and tight tolerances, but even minor imbalance can throw off an entire production run. We provide advanced balancing for spindles and CNC tooling to minimize runout and tool vibration, ensuring optimal performance. This ensures cleaner finishes, longer tool life, and fewer rejected parts. Detroit’s aerospace and automotive industries rely on our spindle balancing services to maintain compliance with exacting standards. We understand that precision isn’t optional—it’s essential to your productivity and reputation.

Industries Served with Custom Dynamic Balancing Programs

Our clients represent a diverse range of industries, and we tailor our balancing programs to meet the specific needs of each one. Automotive manufacturers utilize our services to maintain assembly line reliability, while aerospace companies rely on us to meet stringent vibration thresholds. We support hospitals and healthcare facilities that depend on uninterrupted air circulation, as well as power plants and data centers that require consistent mechanical performance. From pulp and paper mills to food processing plants, we build lasting relationships with clients who value uptime, safety, and cost control. Our customized balancing solutions ensure that each industry gets precisely what it needs to keep operations running smoothly.

How Our Balancing Process Ensures Long-Term Equipment Health

Our dynamic balancing process begins with a comprehensive inspection, which includes reviewing the equipment’s history, conducting a visual assessment, and taking vibration readings. Once we identify the source of imbalance, we determine the necessary correction using precise measurement tools and industry-standard software. Depending on the situation, we may adjust mass distribution by adding counterweights, removing material, or fine-tuning alignment. After adjustments are made, we test the equipment again to ensure the problem is fully resolved. Our final report provides all diagnostics, corrections made, and future maintenance suggestions. By implementing our process, clients benefit from longer equipment life, lower operating costs, and better overall reliability.

Why Detroit Businesses Trust Dynamic Balancing Technologies

Trust is earned through results. Our Detroit clients consistently rely on us for our professionalism, technical expertise, and rapid response. We offer competitive pricing without compromising on quality, making us the top choice for affordable dynamic balancing services in Michigan. From emergency field balancing to scheduled maintenance programs, we provide dependable service that fits your timeline and budget. Our long-standing reputation is built on transparency, data-driven decisions, and a genuine commitment to helping your business succeed. With Dynamic Balancing Technologies, you’re not just hiring a technician—you’re gaining a partner who prioritizes your success.

Frequently Asked Questions (FAQ)

What equipment can benefit from dynamic balancing?

Any equipment with rotating components can benefit from dynamic balancing. This includes motors, fans, pumps, blowers, impellers, turbines, spindles, and other related components. Balancing helps reduce vibration, extend equipment life, and improve efficiency.

Is on-site balancing available in the Detroit metro area?

Yes, we offer comprehensive field balancing services throughout Detroit and its surrounding cities. Our portable equipment allows us to perform on-site diagnostics and correction with minimal disruption to your operations.

What’s the difference between static and dynamic balancing?

Static balancing is used to correct single-plane imbalances on stationary or slow-speed components. Dynamic balancing is a more complex process that addresses multi-plane imbalances that occur during rotation. Both are crucial depending on the application.

How long does a balancing service typically take?

Service duration depends on the size, complexity, and condition of the equipment. Some on-site jobs can be completed in a few hours, while more complex balancing may take a full day or require return visits for optimal results.

How often should I perform vibration analysis on my machines?

We recommend performing vibration analysis at least once per year, or more frequently for critical or high-speed equipment. Regular analysis helps catch issues early, reducing the risk of failure and expensive repairs.

Contact Us for Expert Dynamic Balancing Methods in Detroit

If you’re looking for proven methods to restore equipment balance, improve efficiency, and extend operational lifespan, we’re ready to help. At Dynamic Balancing Technologies, we take pride in delivering effective balancing services tailored to your industry. Whether you need vibration diagnostics, rotor balancing, or laser shaft alignment, we have the tools and knowledge to make it happen. Don’t let imbalance cause costly downtime or unnecessary repairs. Contact us today to learn how our team can support your machinery and help your business run at its best.

Address: 295 North Main Street, Romeo, MI 48065

Phone: (586) 280-8256

Email: dynamicbalancingtech@gmail.com