Our Services

We Are Professional Vibration Analysis, Static and

Dynamic Balancing

Vibration Analysis

Vibration analysis is the process of analyzing vibrations in machinery to detect and diagnose potential problems or malfunctions.

Static and Dynamic Balancing

Static balancing balances stationary objects, while dynamic balancing balances rotating objects to minimize vibrations and prevent equipment failure.

Predictive Maintenance

Predictive maintenance is a proactive maintenance strategy that uses data analysis and machine learning to predict equipment failure before it occurs.

Field Balancing

Industrial field balancing involves the measurement and adjustment of unbalanced rotating machinery to improve their performance, reliability, and safety.

Service Industries

Our service industries encompass a range of sectors, from manufacturing and energy production to healthcare and defense, to meet customer needs.

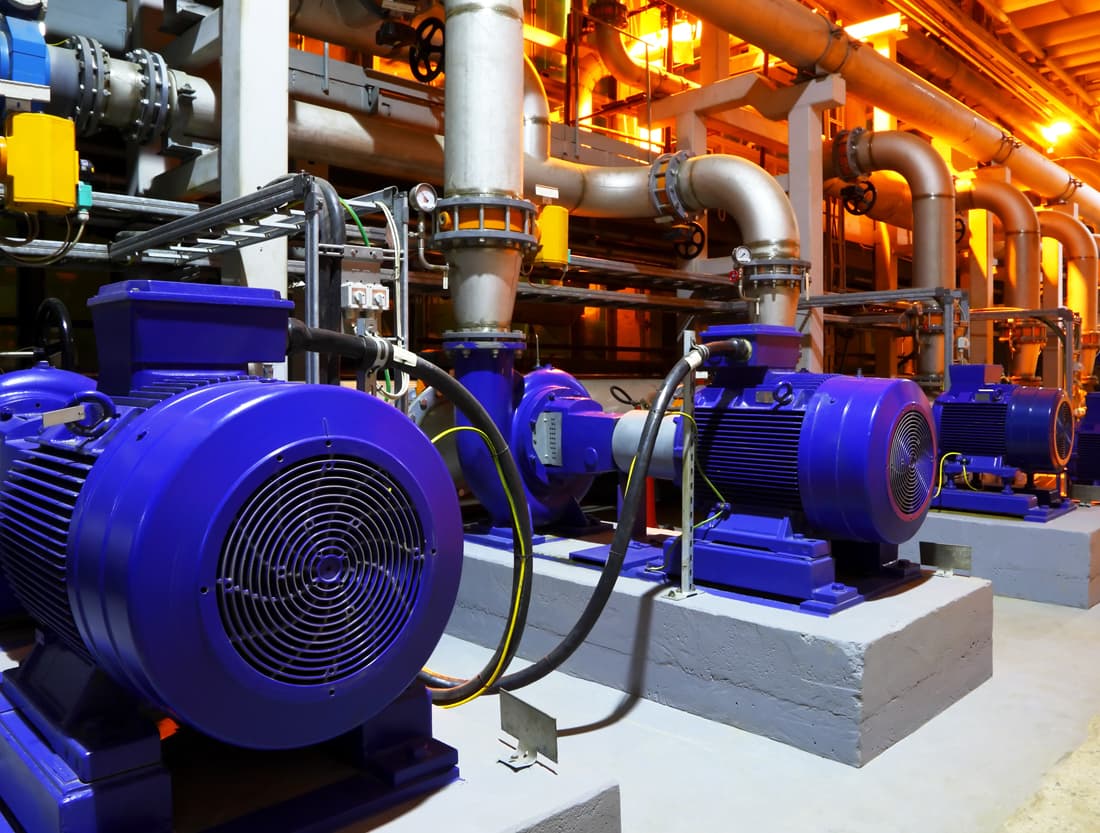

Electric Motor Repair

Inspections from 1 unit up to 200 units. Programs available quarterly, biannually, or annually. We help minimize costly downtime and catch service issues before they become problems.

Comprehensive Service Process

Initial Assessment

The first step is to conduct an initial assessment of the client's equipment and needs. This may involve on-site inspections, equipment history review, and discussions with the client to determine their specific requirements.

Service Proposal

Based on the initial assessment, the company will develop a service proposal that outlines the scope of work, timeline, and cost estimates. The proposal will be presented to the client for review and approval.

Service Execution

Once the service proposal is approved, the company will begin the service execution process. This may involve performing vibration analysis, static and dynamic balancing, and preventative maintenance services as needed, both on-site and in the laboratory.

Follow-up Report

After the service execution is complete, the company will provide follow-up and reporting to the client. This may include detailed analysis reports, maintenance recommendations, and ongoing support as needed to ensure the client's equipment remains in optimal condition.

Additional Services

Industrial Fan Balancing

Industrial fan balancing involves the measurement and correction of unbalance in rotating fans to improve their efficiency, reduce vibration, and prevent premature failure.

Electric Motor Balancing

Electric motor balancing involves the correction of unbalance in rotating electric motors to improve performance, reduce vibration, and extend their service life.

Dynamic Balancing and Analyzing Services

It improves the performance and reliability of rotating equipment by identifying and correcting issues related to unbalanced vibration and resonance.

Brake and Inertia Dynamometer dynamic balancing

Brake and inertia dynamometer dynamic balancing correct unbalance in rotating components of a vehicle or machine to improve their performance, efficiency, and reliability.

Model Scale Wind Tunnel Testing

It plays a crucial role in the development of aircraft, vehicles, and other structures by simulating airflow around scaled models to collect data on their aerodynamic performance, which can then be analyzed to optimize the design.