At Dynamic Balancing Technologies, we understand the crucial connection between equipment longevity and commercial dynamic balancing. In industrial environments where rotating machinery is central to production, every component must operate with precision and reliability. Over time, even the most finely tuned equipment can develop imbalances that compromise performance. These subtle issues often go unnoticed until they result in costly repairs or complete system failure. That’s where our commercial dynamic balancing services come in. By addressing imbalances proactively, we extend the operational lifespan of machinery, optimize energy consumption, and help our clients in Detroit, MI, and beyond achieve more reliable output from their assets.

The Role of Commercial Dynamic Balancing in Industrial Equipment Performance

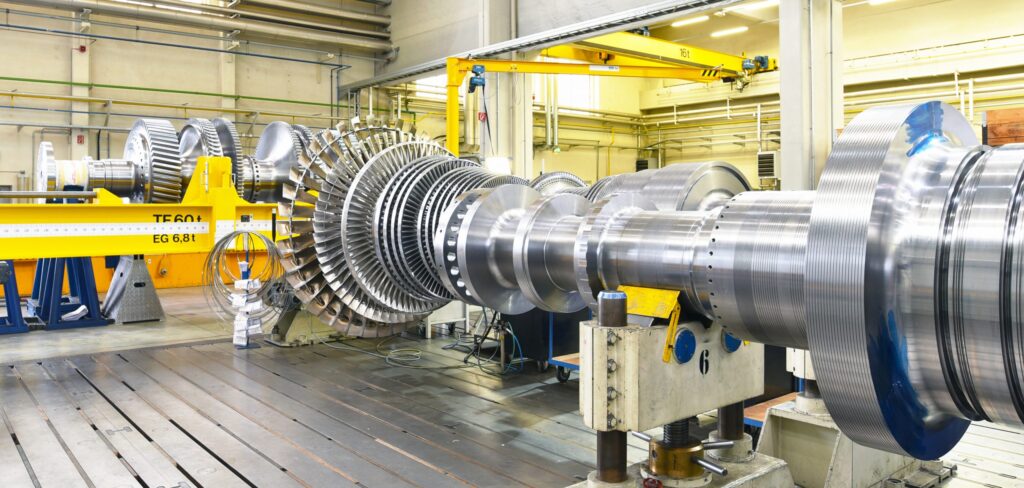

Rotating machinery is at the heart of many commercial operations across Detroit and the Midwest. Motors, fans, pumps, compressors, and spindles are just a few examples of components that must spin smoothly and precisely. When even a slight imbalance occurs—whether due to wear, manufacturing variances, or buildup of debris—it can cause excessive vibration. That vibration doesn’t just affect performance; it accelerates bearing wear, contributes to misalignment, increases operating noise, and eventually leads to mechanical failure. Our commercial dynamic balancing services are designed to prevent these issues at their source.

By applying precision balancing techniques aligned with ISO 1940 standards, we redistribute the mass of rotating parts to ensure that the center of gravity matches the actual axis of rotation. This process significantly reduces vibration, decreases stress on bearings and couplings, and enhances the overall reliability of the machine. With our specialized equipment and decades of experience, we serve a range of industries including automotive, aerospace, energy production, healthcare, food processing, and more. Regardless of the application, we tailor our approach to meet the specific demands of the machinery and industry.

Why Equipment Longevity Depends on Proper Balancing Techniques

Imbalance leads to more than just poor performance—it also shortens the machine’s lifespan. Unchecked vibration creates continuous mechanical stress, particularly in high-speed or heavy-load environments. Bearings, seals, and couplings are subjected to uneven forces that can degrade their integrity over time. This kind of stress often results in microcracks, looseness, fatigue, and misalignment, all of which compromise the machinery’s ability to operate efficiently.

At Dynamic Balancing Technologies, our goal is not only to resolve immediate performance issues but also to ensure the longevity of your equipment. Our balancing services are preventative. By identifying and correcting imbalances before they cause damage, we help clients avoid the cycle of reactive maintenance and expensive part replacement. Balanced machinery operates cooler, quieter, and with reduced friction, which translates to a longer service life and reduced operational costs. Over time, these benefits contribute to increased return on investment for every machine you operate.

Our Expertise in Commercial Dynamic Balancing Services

As a leading mechanical engineer and industrial equipment service provider in Michigan, our firm has over 32 years of experience in the field of dynamic balancing. At our facility in Romeo, MI, and through our on-site service teams across Detroit and neighboring states, we work with industries that rely on the seamless operation of their machinery. Our certified professionals adhere to global balancing standards and use the latest technology to analyze vibration levels and implement corrective solutions.

We work closely with manufacturers, maintenance teams, and facility operators to design custom balancing programs that address current performance concerns while also supporting the long-term health of their equipment. Whether you’re running a large-scale production facility or maintaining a mission-critical HVAC system, our approach is consistently grounded in technical accuracy, exceptional customer support, and reliable outcomes. Clients choose us because we provide commercial balancing solutions that are affordable, data-driven, and scalable to both small operations and large industrial networks.

In-Shop and On-Site Dynamic Balancing for Rotating Components

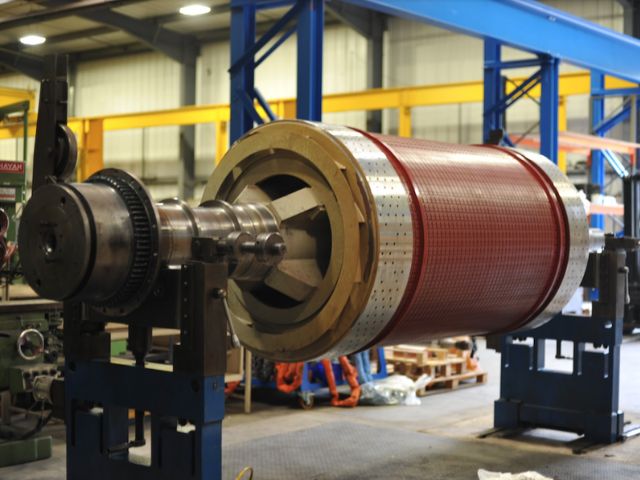

Our balancing capabilities include both in-shop and field services. In our Romeo facility, we handle a wide variety of rotating components, including fans, impellers, rotors, electric motors, spindles, and blowers. For parts up to 250 pounds, we use high-precision dynamic balancing machines to achieve balance across multiple planes. We utilize real-time digital readings to guide each correction, ensuring the final product meets all required specifications.

For clients who cannot remove their equipment or need rapid turnaround, we offer on-site dynamic balancing across the Detroit metro area. Our mobile teams arrive equipped with portable instruments to assess and correct imbalance issues without disassembly or extended downtime. This flexibility allows us to serve industries where time is critical, such as hospitals, energy plants, and production facilities. By bringing the service directly to our clients, we eliminate transportation logistics while ensuring that balancing is completed with the same level of precision as in our workshop.

Precision Static Balancing for Low-Speed and Stationary Machinery

Static balancing plays a vital role in situations where dynamic movement is limited or when components rotate at lower speeds. Many parts, such as pulleys, wheels, couplings, and large gears, may not reach the speeds necessary to reveal dynamic imbalances but still require proper weight distribution. In these cases, we conduct single-plane static balancing to ensure that there are no heavy spots that could cause equipment to roll or sit unevenly.

This type of balancing is crucial for applications where stability and longevity are prioritized over speed, such as in standby systems, emergency backup machinery, or rotating structural devices. We offer both diagnostic and corrective services, ensuring your equipment starts balanced and stays balanced throughout its lifecycle.

Comprehensive Vibration Analysis for Predictive Maintenance

To maintain a proactive stance on equipment health, we integrate commercial dynamic balancing with our in-depth vibration analysis services. This approach enables us to identify emerging issues, such as imbalance, misalignment, looseness, or bearing failure, before they result in downtime. Using tools that measure waveform, frequency, velocity, and acceleration, we build a detailed profile of your machinery’s performance.

Our vibration diagnostics are particularly valuable for predictive maintenance strategies. Instead of waiting for a problem to interrupt your operation, we offer data that forecasts future wear or failure points. These insights allow your maintenance team to schedule repairs in advance, reduce risk, and lower overall maintenance costs. Every vibration report we deliver includes recommended actions, balance verification, and data you can use to improve equipment scheduling and budget planning.

Laser Shaft Alignment: Protecting Couplings, Seals, and Bearings

Misalignment is one of the leading causes of machinery failure, often resulting in damaged seals, increased energy usage, and excessive bearing wear. Our laser shaft alignment services eliminate this risk by ensuring all interconnected components—such as motors, pumps, and gearboxes—are perfectly aligned at the micron level. We use advanced calibration tools to measure angular and parallel misalignment, then make real-time adjustments until the system achieves optimal configuration.

This service is especially crucial for high-speed or high-load environments, where even a slight degree of misalignment can lead to catastrophic failure. By maintaining proper shaft alignment, we reduce vibration, extend the life of couplings and seals, and promote overall system efficiency. Our alignment services support a wide range of industries in Detroit, including HVAC, energy generation, water treatment, and industrial manufacturing.

Fan, Blower, and Electric Motor Balancing for Industrial Facilities

Fans, blowers, and electric motors are some of the most vibration-sensitive components in industrial environments. From HVAC systems in office buildings to blowers in food processing plants, these components must operate efficiently and reliably. At Dynamic Balancing Technologies, we provide specialized balancing services that restore the proper operation of these components.

Unbalanced fans and motors can lead to excessive noise, reduced airflow, overheating, and premature wear. Our technicians analyze each unit, perform corrective balancing, and verify results with follow-up vibration readings. This service enhances energy efficiency, prolongs equipment life, and helps facilities remain compliant with regulatory requirements. We also assist in diagnosing and resolving complex vibration issues that may arise from improper installation or operational wear.

CNC Spindle and Tooling Balancing for Manufacturing Precision

In manufacturing environments such as aerospace and automotive production, CNC machines and high-speed spindles play a vital role in achieving precision. Any imbalance in spindle tooling can result in poor surface finishes, accelerated tool wear, and even machine failure. Our spindle balancing services are designed to address these challenges with extreme accuracy.

We utilize high-speed balancing machines that can detect even the slightest deviation from optimal mass distribution. Whether you’re working with horizontal or vertical spindle configurations, our balancing services ensure your tools operate at peak performance. This not only improves product quality but also increases tool longevity and reduces downtime associated with rework and part rejection.

Industry Applications of Our Commercial Dynamic Balancing Services

The need for equipment reliability spans every sector, and our services reflect that diversity. In the automotive industry, we help maintain assembly line efficiency by balancing driveshafts, fan blades, and electric motors. Aerospace clients rely on our services for precise spindle control and stringent vibration tolerances. Food processors rely on us for blower and motor balancing, which supports hygienic, uninterrupted production.

We also serve paper mills, power generation facilities, data centers, and healthcare institutions where uptime and system health are critical. Each industry requires a slightly different approach to balancing, and our team is skilled at developing solutions that are both technically sound and operationally efficient. We tailor our strategies to meet the specific demands of your equipment, environment, and operational goals.

Step-by-Step: How We Enhance Equipment Longevity Through Balancing

Every service we provide begins with a thorough evaluation. We start with a visual inspection, a review of operational data, and vibration diagnostics to understand the machine’s current state. Next, we determine whether static or dynamic balancing is appropriate and proceed with the proper correction method. Once balanced, we retest the equipment to confirm the problem has been resolved.

Finally, we provide a comprehensive report detailing the issues found, the balancing actions taken, and our recommendations for future maintenance. This process ensures that your equipment is not only balanced but also integrated into a long-term strategy for performance and longevity. Our focus on data-driven diagnostics, precise corrections, and transparent reporting gives our clients the confidence to operate at full capacity with minimal risk.

Why Choose Dynamic Balancing Technologies in Detroit, MI

We’ve built our reputation on more than just technical ability. Our clients return to us because we’re responsive, dependable, and genuinely committed to the success of their operations. We offer affordable commercial dynamic balancing services designed to protect your equipment and your bottom line. From emergency on-site support to scheduled shop balancing, we adapt to your needs and timeline.

As a top-rated provider in Detroit, we combine traditional mechanical knowledge with advanced tools and modern diagnostics. Our certified professionals maintain high standards for safety, performance, and customer satisfaction. When you work with us, you gain a partner who prioritizes your goals and delivers real value every time.

Frequently Asked Questions (FAQ)

What are the signs that my equipment needs balancing?

You may notice excessive vibration, increased noise, bearing failure, uneven wear, or higher energy consumption. These are often indicators of imbalance and should be addressed promptly.

How often should dynamic balancing be performed on industrial machinery?

It depends on the application, but most critical systems should be inspected and potentially balanced annually or during routine maintenance intervals. High-speed systems may require more frequent checks.

Is dynamic balancing more cost-effective than part replacement?

Absolutely. Balancing corrects the root cause of many mechanical failures, reducing the need for expensive replacements and unplanned downtime. It’s a preventative investment with long-term benefits.

Do you offer on-site services for large or fixed equipment?

Yes, we provide mobile field balancing services across Detroit and the surrounding Midwest. Our portable tools allow us to perform precision balancing without removing the equipment.

Can vibration analysis predict mechanical failure?

Yes. Vibration analysis is a crucial component of predictive maintenance, enabling the detection of early-stage issues such as misalignment, imbalance, and bearing wear, thereby allowing for proactive intervention before failure occurs.

Contact Us to Maximize Equipment Lifespan with Commercial Balancing

If your machinery is exhibiting signs of imbalance, excessive vibration, or unexpected wear, it’s time to take action. At Dynamic Balancing Technologies, we provide reliable and cost-effective commercial dynamic balancing services that extend equipment life and prevent costly breakdowns. Let us help you maintain your competitive edge with customized solutions built for your industry.

Address: 295 North Main Street, Romeo, MI 48065

Phone: (586) 280-8256

Email: dynamicbalancingtech@gmail.com