At Dynamic Balancing Technologies, we know that optimizing equipment performance with balancing techniques is one of the most effective ways to extend machinery life, increase productivity, and minimize costly downtime. Whether your operations involve manufacturing, aerospace, HVAC, or energy production, the health of your rotating machinery is crucial to daily performance. Even the slightest imbalance can lead to accelerated wear, vibration, energy waste, and ultimately, failure. That’s why our clients throughout Detroit rely on us to deliver precision balancing solutions that correct these inefficiencies at their core.

The Link Between Equipment Performance and Mechanical Balance

Balancing is the hidden key behind smooth-running industrial operations. When machines rotate, their components must distribute mass evenly to avoid excessive vibration. Even a slight imbalance in a fan, motor, shaft, or rotor creates a centrifugal force that strains the entire system. This force not only reduces operational efficiency but also leads to increased noise, energy consumption, and premature wear.

Through our tailored balancing techniques, we eliminate these stressors by aligning the center of mass with the axis of rotation. This process minimizes vibration, reduces the load on bearings and couplings, and enables your equipment to operate at its full potential. In a fast-paced industrial environment like Detroit, where uptime and performance are critical, proper balancing is not optional—it’s essential.

Dynamic Balancing Techniques That Improve Rotating Equipment Efficiency

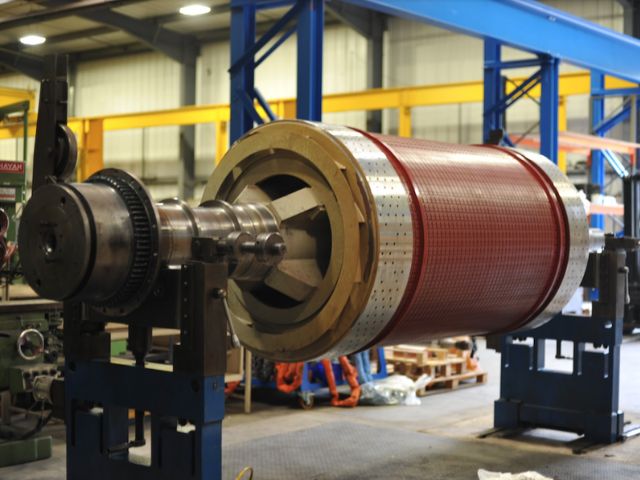

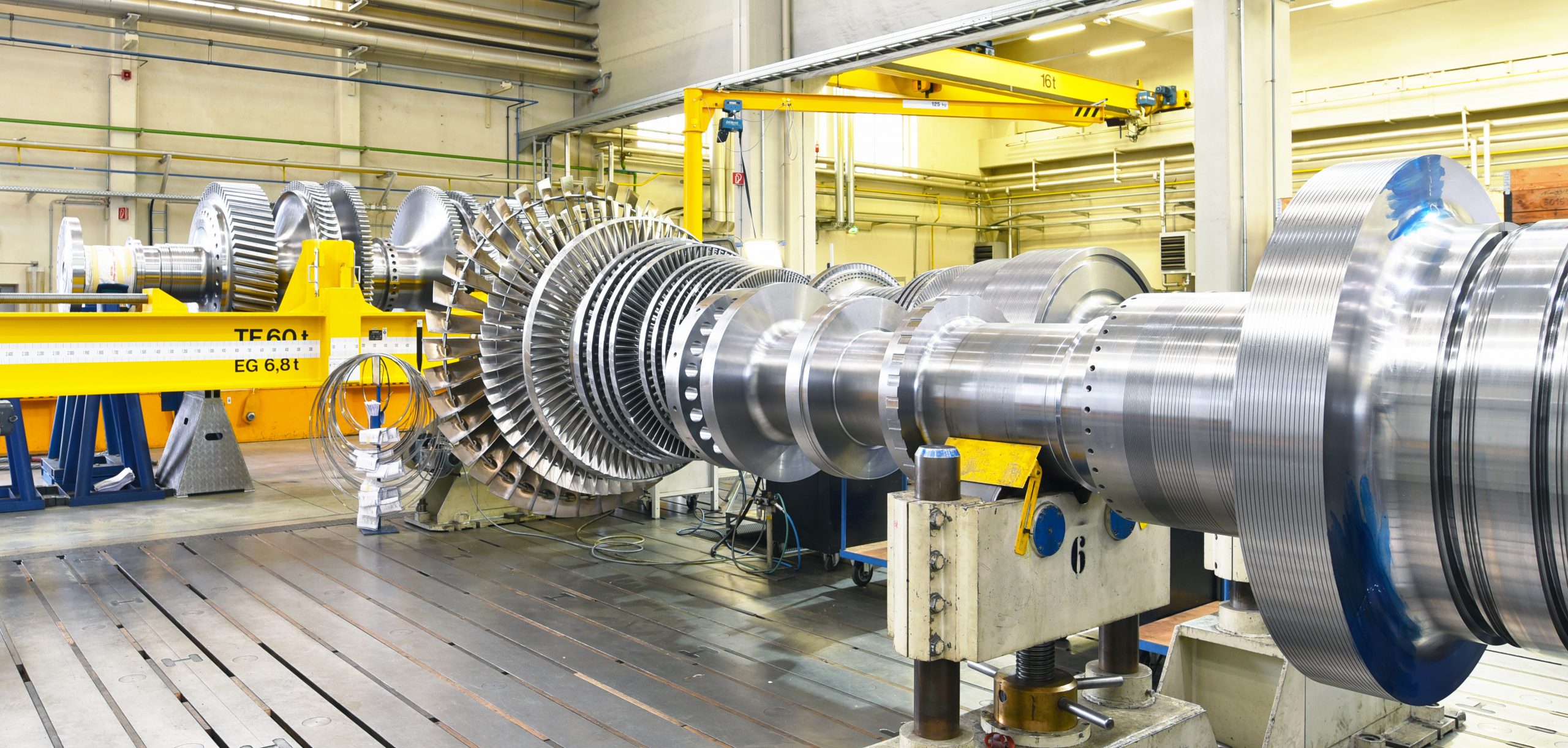

Dynamic balancing is a core service we provide to industries that rely on high-speed or heavy-duty rotating equipment. This method involves identifying and correcting imbalance while the component is in motion. By analyzing vibration patterns in real-time and making precise weight adjustments, we bring the rotating element into optimal balance.

We routinely apply dynamic balancing to a wide range of components, including fans, impellers, electric motors, rotors, and blowers. Each element is evaluated using high-tech instruments that capture vibration velocity, frequency, and phase. Once diagnosed, we correct the imbalance by adding or removing mass in specific locations, ensuring that the part rotates with minimal eccentricity. The result is smoother performance, reduced maintenance costs, and extended equipment life.

Our clients in Detroit value this service because it enhances equipment efficiency, allowing for uninterrupted production. Whether you’re operating an assembly line or managing facility HVAC systems, dynamic balancing keeps your systems running reliably and quietly.

Why Static Balancing Matters in Low-Speed Equipment Optimization

While dynamic balancing is used for high-speed machinery, static balancing plays an equally important role for slower-speed and stationary equipment. This balancing method corrects mass distribution errors in components that do not require multi-plane corrections. When a pulley, gear, or wheel consistently settles into one position, it indicates the presence of a heavy spot. Left unaddressed, this imbalance can lead to instability, misalignment, and uneven wear over time.

At Dynamic Balancing Technologies, we provide static balancing services that address these issues at their root cause. Our technicians use single-plane correction to eliminate unwanted mass concentration and restore proper balance. This ensures that low-RPM machinery and stationary rotating components maintain optimal stability. From emergency backup systems to structural rotating parts in heavy-duty machinery, our static balancing methods deliver consistent and lasting results.

The Role of Vibration Analysis in Equipment Optimization

To effectively optimize performance, you must first understand the current condition of your machinery. That’s where vibration analysis comes in. We utilize this diagnostic tool to gather real-time data on the operational state of your equipment. By analyzing parameters such as acceleration, velocity, and frequency, we can pinpoint issues like imbalance, misalignment, mechanical looseness, or bearing failure.

This analysis is the foundation of our optimization strategy. Before performing any balancing corrections, we conduct a thorough vibration assessment to ensure we understand the full scope of the problem. For many of our clients in Detroit, vibration analysis is part of an ongoing predictive maintenance program. By identifying issues early, they can avoid unexpected breakdowns and schedule maintenance at the most convenient times.

Our detailed reports are more than just data—they are actionable insights. We interpret the findings, explain the implications, and recommend specific balancing techniques that will enhance equipment performance. With this proactive approach, our clients make informed decisions that save time, money, and resources.

Precision Laser Shaft Alignment for Energy and Wear Reduction

Proper alignment is critical for any interconnected rotating machinery. Misaligned shafts create additional stress on couplings, bearings, and seals, leading to inefficiency and mechanical failure. Laser shaft alignment ensures that all components are correctly positioned, reducing friction and enabling the system to function at peak performance.

Our laser alignment services utilize high-precision equipment that can detect micrometer-level deviations. Once identified, we adjust the shafts to achieve perfect parallel and angular alignment. This technique significantly improves energy transfer efficiency, reduces component fatigue, and extends the lifespan of machinery.

Common applications for shaft alignment include pumps, gearboxes, compressors, and motors—all of which are found in abundance across Detroit’s industrial landscape. When aligned properly, these machines consume less energy and operate with greater mechanical harmony, which translates directly into long-term savings and reliability.

Optimizing Performance of Industrial Fans, Blowers, and Motors

Fans, blowers, and motors are often the backbone of facility-wide systems, especially in HVAC, energy, and manufacturing operations. These components are also highly susceptible to performance degradation caused by imbalance. Increased noise, airflow disruption, overheating, and mechanical vibration are common symptoms of imbalance in these systems.

We specialize in restoring efficiency through fan and motor balancing services tailored to your specific applications. Our technicians conduct thorough inspections, evaluate rotational behavior, and apply corrections to ensure even mass distribution. Following balancing, we conduct a vibration analysis to confirm the improvements and verify that the equipment is operating within acceptable parameters.

By addressing imbalance in these components, we help our clients improve airflow, lower power consumption, and reduce maintenance frequency. For facilities in Detroit that demand consistent climate control, energy efficiency, and operational uptime, this service is invaluable.

CNC and Spindle Tool Balancing for High-Precision Operations

In industries such as aerospace, defense, and advanced manufacturing, CNC machines and spindle tools are vital assets. These high-speed machines require perfect balance to deliver accurate results, maintain tight tolerances, and reduce cycle times. Any imbalance can introduce runout, chatter, and surface finish issues that compromise the quality of the final product.

Our spindle balancing services are designed to support these high-precision environments. We balance rotating tool holders, spindles, and chucks used in CNC applications to eliminate even the slightest deviations. By reducing vibration, we not only enhance tool life and machining speed but also improve product consistency and surface integrity.

For Detroit’s manufacturing sector, where production quality and throughput directly impact competitiveness, optimizing CNC performance with spindle balancing is a strategic advantage. We collaborate with manufacturers across various sectors to ensure production efficiency and maintain exacting quality standards.

Real-World Benefits of Optimizing Equipment with Balancing Techniques

Balancing techniques offer more than just technical benefits—they provide strategic value to your operation. When machinery runs smoothly, it lasts longer, consumes less energy, and performs more consistently. Fewer breakdowns mean fewer emergency repairs and reduced labor costs. Enhanced balance also improves safety by minimizing the risk of equipment malfunction during operation.

In addition to operational advantages, balancing extends the lifespan of critical components such as bearings, seals, and couplings. This results in less frequent replacement, fewer disruptions, and improved overall equipment effectiveness. Over time, these improvements result in a higher return on investment and stronger performance metrics.

At Dynamic Balancing Technologies, we see these results firsthand. Our clients in Detroit regularly report decreased energy usage, increased productivity, and lower total cost of ownership after implementing our balancing services. For any organization looking to optimize performance, these techniques are not just an option—they are a requirement.

Why Choose Dynamic Balancing Technologies for Your Equipment Optimization Needs

With over three decades of hands-on experience and a team of certified experts, we have become Detroit’s trusted partner for balancing and equipment performance optimization. Our services are built on the principles of precision, reliability, and customized client focus. We understand that each machine, application, and industry has unique needs, and we tailor our approach to meet these needs accordingly.

Our facilities in Romeo, MI are equipped with advanced dynamic balancing systems, and our field teams are mobile, responsive, and ready to serve clients across the Midwest. Whether you’re in automotive production, medical device manufacturing, or power generation, we offer balancing solutions that align with your goals for uptime, quality, and efficiency.

We are recognized across Google Business Profile categories as a mechanical engineer, machine shop, industrial equipment supplier, and maintenance service. This range of services allows us to support every aspect of your machinery’s performance and lifecycle—from initial installation and diagnostics to regular balancing and predictive maintenance.

Frequently Asked Questions (FAQ)

How does balancing extend the life of my equipment?

Balancing minimizes mechanical stress on rotating components, which reduces wear on bearings, couplings, and seals. This allows the equipment to run longer and more reliably without premature failure.

What’s the difference between dynamic and static balancing?

Dynamic balancing corrects imbalance while the part is in motion and can handle multi-plane corrections. Static balancing is done on stationary parts and addresses single-plane imbalance, typically in slower-speed applications.

Can I optimize performance without removing equipment?

Yes. Our field technicians provide on-site balancing and alignment services using portable tools. This allows us to perform diagnostics and corrections without disassembling your machinery.

How often should vibration analysis be conducted?

We recommend vibration analysis at least once per year for standard equipment and more frequently for high-speed or mission-critical systems. Regular analysis ensures early detection of imbalance and other issues.

What types of equipment can benefit from laser alignment?

Laser shaft alignment is beneficial for any machinery that connects via shafts—such as pumps, motors, compressors, and gearboxes. Proper alignment improves efficiency, reduces wear, and enhances performance.

Contact Us for Expert Equipment Performance Optimization

If your equipment is underperforming or showing signs of imbalance, don’t wait for failure to strike. At Dynamic Balancing Technologies, we are committed to helping Detroit’s industries operate more efficiently, safely, and profitably. Our balancing techniques are rooted in engineering precision and field-tested experience.

We invite you to contact us to learn more about how we can enhance the performance of your machinery. Whether you need a one-time balance correction or a long-term maintenance partnership, we’re ready to help your operation succeed.

Address: 295 North Main Street, Romeo, MI 48065

Phone: (586) 280-8256

Email: dynamicbalancingtech@gmail.com