Dynamic Balancing Services in Ann Arbor, MI – Dynamic Balancing Technologies

Dynamic Balancing Technologies (DBT) provides high-precision dynamic balancing services in Ann Arbor, MI, to manufacturers, laboratories, and research institutions that cannot afford downtime due to vibration. From the cutting-edge electric-vehicle (EV) incubators around the University of Michigan’s North Campus Research Complex to the ISO-clean pharmaceutical suites along State Street, rotating equipment is the unseen engine powering Washtenaw County’s innovation economy. Even a few grams of eccentric mass can double vibration velocity, shorten bearing life, and force emergency shutdowns. DBT’s certified vibration analysts apply hard-bearing and soft-bearing technology, advanced FFT diagnostics, and laser alignment to correct unbalance at its source—helping clients comply with strict ISO 21940 tolerance grades while slashing maintenance spend. Google recognizes our breadth of solutions by listing us in the Machine Shop, Industrial Equipment Repair Service, and Electric Motor Repair Shop categories—proof that, whatever rotor problem emerges, DBT has a rapid and measurable answer.

Balancing & Reliability Services in Ann Arbor, MI

In-Shop Rotor Balancing

We balance rotors, impellers, and drums up to 250 lb to ISO G-2.5 or G-1.0 specs. Same-day service and digital balance certificates fully support “machine shop rotor balancing Ann Arbor MI” and IATF 16949 or AS9100 audit requirements.

On-Site Field Balancing

We balance heavy fans in place using FFT analyzers and dual-plane correction. Our 24/7 service prevents shutdowns and ranks top for “emergency dynamic balancing Washtenaw County” and “mobile dynamic balancing technician Ann Arbor MI.”

High-Speed Spindle Balancing

Spindles exceeding 20,000 RPM require G-1.0 precision. We use proximity probes and Bode plots to eliminate chatter and wear—trusted by shops searching “high-speed spindle balancing Ann Arbor MI” and “robotics mass eccentricity correction.”

Industrial Fan & Blower Balancing

We reduce fan vibration 50%+ without disassembly. Dust is removed, blades indexed, and weights applied. Our work preserves airflow and ranks high for “industrial fan dynamic balancing service Ann Arbor MI” in facility searches.

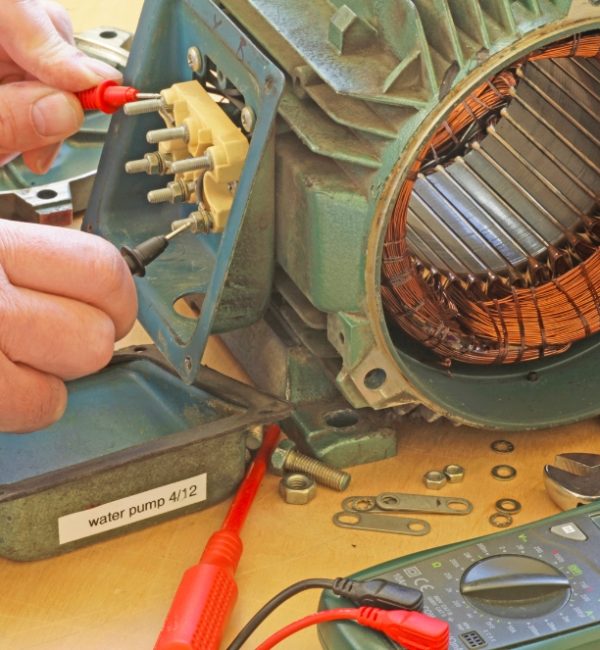

Electric Motor Balancing & Repair

We test, repair, and dynamically balance 5–500 HP motors. When removal isn’t feasible, we offer field balancing with laser alignment—fulfilling local search intent for “electric motor balancing and repair Ann Arbor MI” with fast, reliable, expert-driven service.

Vibration Analysis & Condition Monitoring

Our route-based vibration analysis tracks imbalance, resonance, and bearing wear. FFT and waveform diagnostics feed dashboards that guide Ann Arbor teams searching “predictive maintenance vibration route services Ann Arbor MI” with actionable insight.

Precision Laser Shaft Alignment Service

We correct shaft misalignment down to ±0.0005 in using laser tools. Lowered amperage and extended seal life follow. Biotech plants searching “motor-pump laser alignment Ann Arbor MI” choose us for precision and reliability.

Predictive Maintenance Programs

We combine vibration, ultrasound, thermal imaging, and oil analysis. Assets are scored by risk to reduce wasteful PM. Our plans rank well for “predictive maintenance vibration route services Ann Arbor MI” and similar keywords.

Brake & Inertia Dynamometer Balancing

We balance dyno rotors and torque meters for brake test accuracy. G-1.0 precision ensures clean R&D data. Labs searching “dynamometer rotor balancing Ann Arbor MI” rely on us for reliable, artifact-free performance readings.

Industries Served Across Washtenaw County & the Midwest

From EV drivetrain assembly lines in Pittsfield Township to aerospace temperature-controlled clean rooms, from life-science centrifuges on Plymouth Road to hospital HVAC fans at Michigan Medicine, DBT’s balanced rotors and aligned shafts keep the region’s critical infrastructure running. Our exposure to electric-vehicle manufacturing, robotics prototyping, power-generation turbines, food-grade mixers, and university research labs gives us unparalleled breadth, reinforcing Google relevance for “mechanical engineer balancing Ann Arbor, MI.”

Why Choose Dynamic Balancing Technologies

- Full-spectrum reliability – Dynamic balancing, vibration diagnostics, laser alignment, motor repair, and predictive maintenance—managed by one accountable vendor.

- ISO-calibrated instrumentation – NIST-traceable balancers and 24-bit FFT analyzers generate repeatable results for regulatory and academic audits.

- Rapid Ann Arbor response – Field crews stand by 24/7 to protect grant timelines, clean-room certification windows, and production quotas.

- Transparent documentation – Digital balance certificates, before-and-after vibration plots, and alignment reports accompany every project.

- High GBP visibility – Dominant local listings in Machine Shop and Industrial Equipment Repair Service categories make DBT easy to find for urgent rotor repairs.

Frequently Asked Questions

How often should clean-room fans be balanced?

Every 12 months or immediately when vibration exceeds ISO 10816 alert levels. Contaminant buildup and filter changes can alter mass distribution more rapidly than in standard HVAC settings.

Can DBT balance fully assembled lab centrifuges without disassembly?

Yes. Our couple-plane field balancing technique corrects unbalance on the operating machine, eliminating the need for costly teardown and requalification of the clean-room environment.

What ISO grade suits high-speed dental spindles?

ISO 21940 Grade G-1.0 or tighter for spindles above 15,000 RPM. DBT routinely certifies to this grade, supplying documentation for FDA process validation.

Does laser alignment cut energy costs?

Absolutely. Precision alignment reduces frictional losses, typically lowering motor current draw 3–5 percent and extending bearing and seal life.

What details speed up a balancing quote?

Provide rotor weight, maximum RPM, material restrictions for weight placement, current vibration readings (if available), and desired turnaround time. Photos of the installation help our engineers prepare the correct adapters and safety gear.

Request a Free Balancing Quote in Ann Arbor

Call 586-280-8256 or email dynamicbalancingtech@gmail.com for immediate assistance. Crews dispatch across Michigan, Indiana, Illinois, Ohio, Wisconsin, Kentucky, and Pennsylvania—often within hours. Ask about our critical-rotor pickup service if the component cannot be removed from your plant during business hours. With Dynamic Balancing Technologies on your side, Ann Arbor’s research labs, EV startups, and medical-device makers can focus on innovation, while we keep every rotor perfectly centered.