Expert On-Site Industrial Field Balancing Services in Warren, Michigan

Industrial machinery requires precise operation to maintain safety, efficiency, and longevity. One of the most overlooked causes of mechanical wear and failure is imbalance in rotating components. At Dynamic Balancing Technologies, we offer professional industrial field balancing in Warren, MI, to ensure your equipment operates at its optimal performance. Our team delivers fast, on-site balancing services that minimize downtime and correct vibration issues where they happen—at your facility. We proudly serve manufacturing plants, machine shops, and other industrial clients throughout Warren and the surrounding Michigan area. Our on-site field balancing services are specifically designed for rotating components, including fans, blowers, spindles, and drive shafts. When you choose our team for on-site dynamic balancing in Warren, you’re choosing a reliable solution that saves you from disassembling equipment or halting production. Our services are designed to optimize performance and eliminate the causes of excessive vibration, noise, and mechanical degradation.

What Is Industrial Field Balancing and Why It Matters

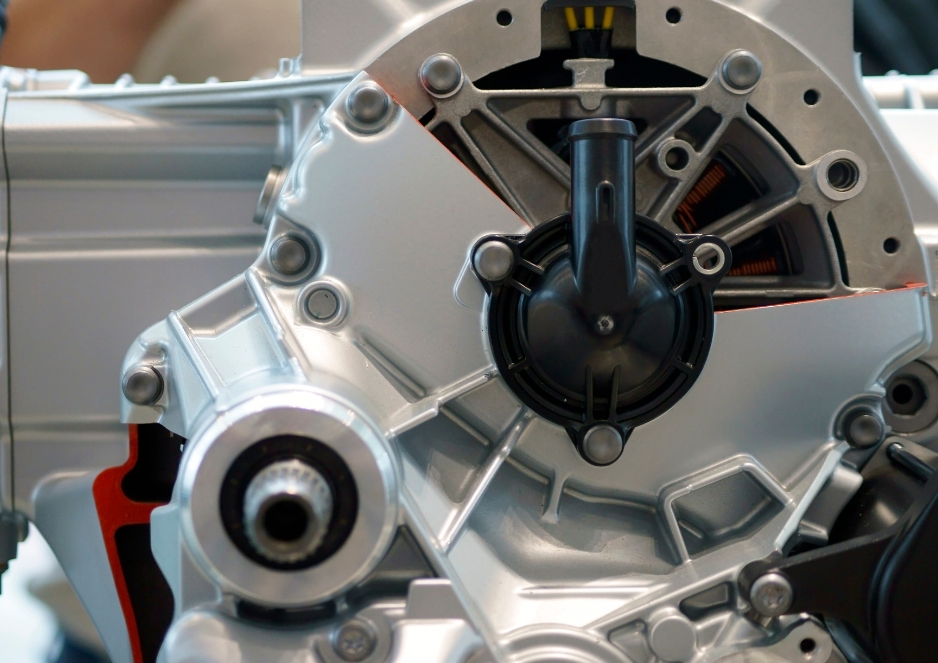

Industrial field balancing is the process of correcting rotor unbalance while the equipment remains installed and in operation. This form of balancing is particularly effective because it considers the rotor’s real-world conditions—temperature changes, load fluctuations, and surrounding structure dynamics—that can impact its balance. There are two primary types of balancing used in industry: static and dynamic. Static balancing addresses imbalance while the component is stationary, while dynamic balancing corrects it while in motion. Dynamic balancing in the field is far superior for high-speed or mission-critical industrial equipment, as it provides more accurate corrections in real time. In-place field balancing delivers a host of benefits. It reduces downtime since there’s no need for disassembly. It also ensures a more precise correction by capturing the actual operating conditions. Imbalances that cause vibration can lead to premature bearing failure, misalignment, and even cracked housings. That’s why we incorporate vibration analysis, predictive maintenance, and phase angle measurements to fully understand what’s happening with your equipment before applying balancing corrections. Entities such as rotor imbalance, vibration analysis, critical speed, and machine reliability all play a role in the outcome. By using high-accuracy diagnostics and skilled technicians, we return your machinery to optimal condition with minimal disruption.

Our Warren Field Balancing Expertise

With over 33 years of experience in dynamic balancing, vibration correction, and rotating equipment diagnostics, Dynamic Balancing Technologies is a leader in industrial services throughout Michigan. Our Warren field team brings a wealth of hands-on knowledge, high-precision equipment, and deep familiarity with local industries. We serve a wide range of operations in Warren, including automotive manufacturers, heavy equipment assembly plants, aerospace suppliers, and utility companies. Whether you operate a small machine shop or a large production facility, our team delivers results with unmatched accuracy and professionalism.

Clients rely on our expertise for field balancing for automotive machinery in Warren and other precision-critical applications. We handle scheduled maintenance, emergency service, and troubleshooting related to vibration. Our goal is to identify imbalance before it escalate into costly repairs or production losses.

What Types of Equipment We Balance On-Site

Our field balancing services in Warren are ideal for most types of rotating machinery used in industrial operations. With portable balancing units and diagnostic software, we’re able to balance the following equipment directly at your facility:

Fans, blowers, spindles, shredders, drive shafts, HVAC systems, and electric motors are among the most commonly balanced components. These parts frequently experience imbalance due to wear, buildup, manufacturing tolerances, or misalignment. Left unchecked, even minor vibrations can lead to significant problems.

Whether you require rotating equipment balancing services for a fan assembly or field rotor balancing in Warren for a high-speed spindle, our technicians are trained to get the job done safely and accurately. We specialize in correcting imbalances in single-plane and two-plane applications, providing a balanced solution that ensures machinery operates smoothly and efficiently.

How the Industrial Field Balancing Process Works

Our process is both systematic and flexible, designed to work around your facility’s schedule while ensuring precision at every stage. It begins with a complete vibration analysis. We utilize diagnostic tools, including FFT analyzers, accelerometers, and tachometers, to assess the equipment’s current operating condition. These tools help us measure vibration levels, identify unbalance vectors, and establish baseline readings. Next, we perform an imbalance diagnosis by interpreting frequency spectra and calculating phase angles. This allows us to pinpoint where corrections are needed. Once the imbalance is located, we apply correction weights to specific planes using our portable balancer. This procedure is executed while the machine is running, allowing us to monitor changes in real time.

After corrections are made, we conduct final testing to verify that vibration levels fall within industry standards, often referencing ISO balance quality grades. We provide clients with a detailed report outlining pre- and post-balancing conditions, diagnostic data, and recommendations for ongoing predictive maintenance. Throughout this process, we focus on entities like balancing weights, rotor response, structural resonance, and long-term machine reliability. Our goal is to solve the problem at its root and ensure lasting performance improvements.

Why Choose Dynamic Balancing Technologies in Warren, MI

When you work with Dynamic Balancing Technologies, you’re choosing more than just a service provider—you’re choosing a partner in performance and reliability. We understand the urgency of minimizing equipment downtime and the importance of striking a balance between precision and efficiency. Our technicians are local to the Warren area, allowing us to respond quickly to both scheduled and emergency calls.

We offer 24/7 support to clients who can’t afford extended downtime. Whether you’re experiencing high vibration, motor noise, or poor part finishes due to spindle issues, we have the tools and expertise to resolve the problem. Our use of advanced balancing techniques and vibration diagnostics ensures that we deliver solutions tailored to your equipment’s unique needs. As trusted Warren industrial balancing experts, we take pride in our transparency, technical accuracy, and commitment to your success. Every job is approached with the mindset of maximizing uptime and machine health.

Serving Warren and Surrounding Michigan Cities

Our services extend beyond Warren to include nearby industrial hubs such as Dearborn, Sterling Heights, Livonia, Flint, and additional areas across southeastern Michigan. Whether you’re located inside Warren’s city limits or in a surrounding county, we bring high-quality on-site rotor balancing near Warren, MI, right to your door.

With our mobile balancing capabilities, we minimize interruptions to your workflow and avoid the cost and complexity of transporting equipment off-site. Regardless of your industry, scale, or urgency, we provide the same high level of service and expertise.

Frequently Asked Questions (FAQs)

How do I know if my machinery needs field balancing?

Common signs include increased vibration, unusual noise, premature bearing wear, and overheating of the equipment. If your machinery is experiencing any of these symptoms, a vibration analysis can confirm the need for balancing.

Can field balancing fix alignment issues?

While field balancing focuses on mass distribution in rotating parts, it often complements alignment services. If misalignment is contributing to imbalance, our team will identify it and may recommend a separate alignment procedure to address the issue.

How long does a typical field balancing service take?

Most balancing jobs take between 2 and 6 hours, depending on the machine’s complexity, the severity of the imbalance, and accessibility. Emergency services may be completed faster if the issue is isolated.

Do you work with both small and large industrial clients?

Yes, we serve businesses of all sizes—from small local shops to primary manufacturing operations. No project is too big or too small for our experienced balancing team.

What makes Dynamic Balancing Technologies different?

Our experience, precision, and commitment to local service set us apart. We offer rapid response in Warren, use the latest vibration diagnostics, and provide transparent reporting with every job.

Contact Us for Industrial Field Balancing in Warren, MI

Don’t wait until vibration damages your machinery or disrupts your operations. Contact Dynamic Balancing Technologies for fast, professional industrial field balancing in Warren, MI. Our team is ready to evaluate your equipment, diagnose the issue, and implement precise balance corrections that extend machine life and reduce repair costs.

Call us at (586) 280-8256 or email dynamicbalancingtech@gmail.com to schedule service. We also offer free consultations to discuss your balancing needs and maintenance goals.

Schedule your on-site balancing service today.

Speak with a Warren-based vibration analysis expert and experience the difference that precision makes.