Vibration Analysis in Warren, MI – Dynamic Balancing Technologies

Dynamic Balancing Technologies is the leading choice for vibration analysis in Warren, MI, providing precision diagnostics and predictive maintenance solutions that keep industrial machinery running at peak performance. With our specialized approach, we help businesses detect mechanical issues early, reduce costly downtime, and extend the lifespan of critical equipment. Our team has decades of combined experience in condition monitoring, machinery diagnostics, and rotating equipment services, enabling us to deliver results that meet the highest industry standards.

Why Choose Dynamic Balancing Technologies for Vibration Analysis in Warren

With more than 33 years of hands-on experience in condition monitoring and machinery diagnostics, Dynamic Balancing Technologies has built a reputation for delivering accurate, timely, and effective solutions. Our primary focus is on predictive maintenance—identifying problems before they escalate into expensive repairs or prolonged downtime. This proactive strategy allows your team to plan maintenance activities during scheduled shutdowns instead of reacting to unexpected failures. We specialize in the diagnostics and maintenance of rotating equipment, from high-speed industrial fans to precision electric motors, ensuring each piece of machinery is balanced, aligned, and operating within safe vibration limits. Our commitment to ISO 10816 compliance guarantees that your equipment is evaluated using internationally recognized vibration measurement standards. We proudly serve Warren’s automotive assembly plants, aerospace component manufacturers, steel mills, and various other manufacturing facilities, delivering tailored services designed to keep operations running at maximum efficiency.

What is Vibration Analysis and How It Works

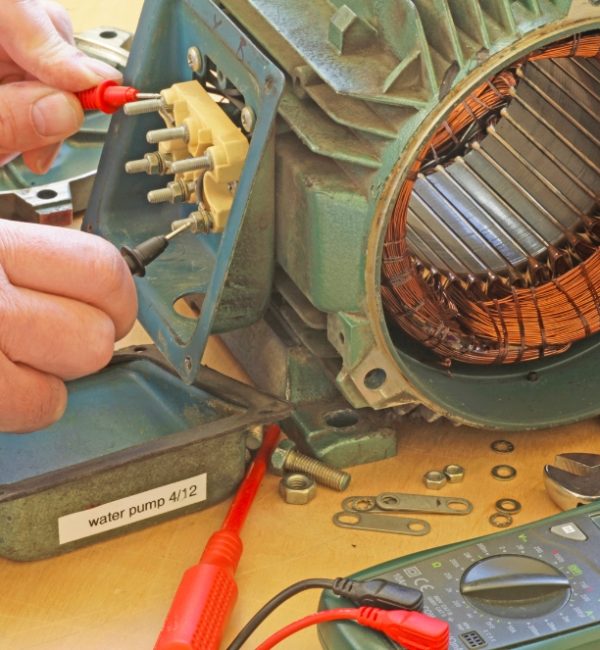

Vibration analysis is a critical diagnostic process that measures and interprets the vibration patterns produced by industrial machinery during operation. Every moving component generates a specific vibration signature, and when that signature changes, it often signals a mechanical problem. At Dynamic Balancing Technologies, we capture these vibration readings using advanced sensors positioned at key locations on the equipment. The data is then processed through Fast Fourier Transform (FFT) analysis and modal analysis techniques, allowing us to identify irregularities that may indicate faults. Common issues detected through this process include imbalance, which causes excessive oscillation and premature wear; misalignment, which can result from improper installation or operational stress; bearing defects, which, if left unchecked, can lead to complete equipment failure; and gearbox problems, where wear, pitting, or lubrication issues disrupt performance. Beyond identifying faults, vibration analysis also provides valuable insights into the overall structural integrity of machinery, enabling ongoing equipment health monitoring and improved decision-making for maintenance planning.

Benefits of Professional Vibration Analysis for Warren Industries

Professional vibration analysis offers Warren’s industrial sector a wide range of benefits, making it an essential part of any comprehensive maintenance program. One of the most significant advantages is early fault detection, which allows plant managers and maintenance teams to address mechanical problems before they escalate into costly breakdowns. By identifying the root cause of vibration-related issues, machinery can be repaired or adjusted to restore smooth operation, significantly increasing reliability and extending equipment lifespan. Improved reliability translates directly into enhanced safety, as malfunctioning equipment poses risks not only to production schedules but also to personnel. For operations relying on rotating machinery, vibration analysis can drastically reduce unplanned downtime, keeping production lines and processes running efficiently. Compliance with established maintenance engineering standards ensures that all diagnostic and corrective measures meet regulatory and industry requirements, further supporting operational excellence and customer confidence.

Our Vibration Analysis Process

At Dynamic Balancing Technologies, our vibration analysis process is designed to provide precise and actionable results. We start with an initial consultation and on-site assessment, where our technicians review your machinery’s operational history and inspect the equipment to determine the best approach for testing. Using advanced accelerometers and other high-sensitivity instruments, we collect vibration data from multiple points on the machine. This data undergoes harmonic analysis and in-depth evaluation to reveal frequency patterns, amplitude levels, and other indicators of mechanical health. Our specialists then perform a detailed frequency spectrum interpretation, comparing findings against baseline measurements and historical trends to identify any changes that may signal developing issues. Based on the results, we present targeted recommendations, which may include dynamic balancing, laser alignment, bearing replacement, or gearbox servicing. After implementing these solutions, we provide follow-up support with periodic condition monitoring to ensure the equipment continues to operate at peak efficiency.

Equipment & Technology We Use

To achieve the highest level of accuracy, we utilize advanced vibration monitoring systems capable of capturing both real-time and historical performance data. Our portable dynamic balancing machines allow for on-site adjustments without dismantling large or complex machinery, saving time and minimizing disruption to operations. For specialized diagnostics, we employ sophisticated signal processing and resonance testing tools that identify even the most subtle equipment irregularities. Real-time monitoring software plays a key role in our predictive maintenance strategies, enabling us to track machine performance continuously and identify potential issues before they impact production. We partner with trusted brands such as Brüel & Kjær, SKF, Fluke, Bentley Nevada, and Emerson AMS to ensure we have access to the most reliable and effective diagnostic tools available in the industry.

Industries We Serve in Warren, MI

Our vibration analysis services are utilized across a broad range of industries in Warren, each with unique operational demands and maintenance challenges. In the automotive manufacturing sector, we help maintain assembly line machinery, ensuring uninterrupted production. For steel mills and metal fabrication facilities, we provide diagnostics for heavy-duty rotating equipment used in high-load environments. Aerospace engineering companies rely on our services to maintain precise tolerances and ensure the safe operation of critical systems. Textile manufacturing operations benefit from our ability to detect and correct high-speed machinery imbalances, while food processing plants depend on our diagnostics to maintain safety, hygiene, and consistent product quality. We also support the power generation and utility industries by monitoring turbines, generators, and other essential machinery to prevent costly outages.

Related Services from Dynamic Balancing Technologies

In addition to vibration analysis, we offer a range of related services that support optimal equipment performance. Our industrial field balancing service addresses imbalances directly at your facility, avoiding the need to remove machinery from service for adjustments. We provide both static and dynamic balancing, ensuring that components operate smoothly and with minimal wear. Our laser alignment services help prevent premature component failures by ensuring precise alignment of shafts and couplings. We also perform electric motor repair and balancing, restoring performance and improving efficiency. For clients looking to take a proactive approach to machinery care, our predictive maintenance programs combine vibration analysis with other diagnostic techniques to create a comprehensive, ongoing equipment management strategy.

Service Areas Around Warren, MI

While our headquarters serves the Warren area, our team provides vibration analysis and related services to a wide range of nearby communities and industrial hubs. Our local presence ensures fast response times for scheduled maintenance as well as urgent service requests. By being readily available to clients across the greater Warren region, we deliver dependable, on-demand diagnostics whenever they are needed.

Why Vibration Analysis is Essential for Warren’s Industrial Sector

In Warren’s competitive industrial landscape, maintaining reliable, efficient machinery is crucial to sustaining productivity and profitability. Vibration analysis plays a key role in preventive maintenance, helping businesses address equipment issues during planned service intervals instead of dealing with sudden, costly breakdowns. This approach not only saves money but also enhances asset performance management, allowing machinery to operate at optimal levels for longer periods. Continuous machine health monitoring supports consistent product quality, improves workplace safety, and helps companies meet production targets without compromise. For industries where precision and reliability are non-negotiable, vibration analysis is a strategic tool that drives operational success.

Frequently Asked Questions (FAQs)

What equipment do you use for vibration analysis?

We use advanced diagnostic technology from respected manufacturers such as Brüel & Kjær, SKF, Fluke, Bentley Nevada, and Emerson AMS. These include high-resolution vibration sensors, portable balancing machines, and specialized analysis software to capture and interpret vibration data with exceptional accuracy.

How often should vibration analysis be performed?

The ideal frequency varies depending on the type of equipment, its usage, and the criticality of its role in production. High-use or mission-critical machinery should be analyzed quarterly or semiannually, while less critical equipment may be monitored annually. We tailor maintenance schedules to match each client’s operational needs.

Can vibration analysis prevent all mechanical failures?

While vibration analysis is one of the most effective tools for identifying early-stage mechanical issues, it cannot prevent every failure. However, it significantly reduces the risk of sudden breakdowns by detecting issues before they become severe, allowing for planned, controlled repairs.

Do you offer on-site balancing services in Warren?

Yes, we provide complete on-site industrial field balancing services throughout Warren and surrounding communities. This allows us to correct imbalances without removing machinery from its operating location, minimizing downtime and reducing costs.

What industries benefit the most from vibration analysis?

Industries that depend on heavy machinery and continuous production gain the most from vibration analysis. Automotive manufacturing, aerospace engineering, steel production, textile manufacturing, food processing, and power generation all benefit from improved reliability, safety, and efficiency when regular vibration monitoring is part of their maintenance program.

Get Started with Professional Vibration Analysis in Warren, MI

If you are ready to improve your machinery’s reliability and extend its operational life, Dynamic Balancing Technologies is here to help. We provide free consultations to evaluate your needs and create a customized vibration analysis plan that aligns with your production schedule. With flexible appointment options and 24/7 emergency on-site services, we are prepared to assist whenever you need us. Serving Warren and the entire Michigan industrial market, we deliver the precision, expertise, and commitment that your business deserves. Contact us today to schedule your vibration analysis and experience the benefits of working with an industry leader in machinery diagnostics.