In Detroit, the industrial sector plays a vital role in preserving America’s automotive and manufacturing legacy. Every day, facilities across the region rely on pumps, motors, compressors, turbines, and spindles to power their production lines. When any of these critical systems fail, operations come to a halt, resulting in expensive repairs and lost productivity. At Dynamic Balancing Technologies, we understand that downtime is not an option for manufacturers in Detroit. That is why we have built our business around providing professional vibration analysis in Detroit, MI, helping facilities prevent failures before they ever occur.

We approach vibration analysis as both a vibration analysis service and a predictive maintenance service. By combining engineering expertise with advanced diagnostic technology, we serve as a trusted mechanical engineering service and consultant for Detroit’s most demanding industries. Our services enable companies to safeguard their investments, enhance safety, and operate with confidence, knowing that machinery health is continually monitored.

Understanding Machinery Failures and the Role of Vibration Testing

Machinery failures rarely happen without warning. In almost every case, equipment gives subtle signs before breakdown. Excessive vibration is one of the most reliable indicators that something is wrong. When a motor shaft is misaligned, a pump becomes imbalanced, or a bearing begins to wear down, vibration signatures change. Without professional testing, these signals are often overlooked, which leads to sudden and costly failures.

Our vibration testing services in Detroit are designed to capture these changes early. We use ISO-calibrated instruments and advanced FFT analyzers to measure vibration levels across multiple axes. This data provides a clear picture of how machinery is performing and whether faults exist. As part of our role in predictive maintenance, we help facilities transition from reactive repairs to proactive strategies. For Detroit’s manufacturing facilities, this means fewer emergencies, fewer shutdowns, and more predictable operations.

Vibration Analysis for Industrial Equipment in Detroit Facilities

Machinery Vibration Testing and Fault Detection

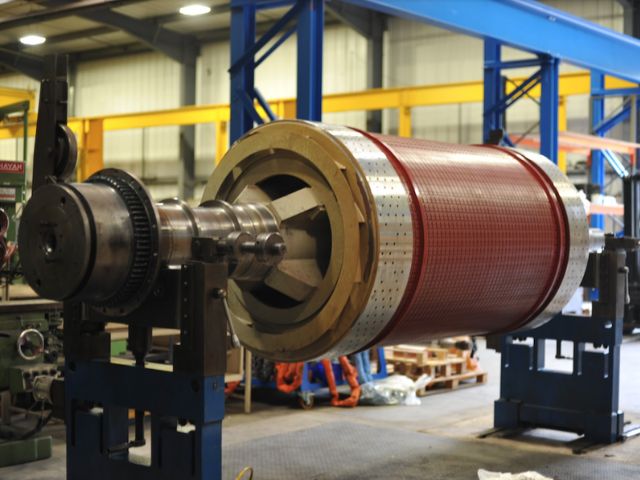

At Dynamic Balancing Technologies, we provide detailed vibration testing for pumps, motors, compressors, and turbines used throughout Detroit facilities. Our diagnostic approach identifies hidden issues, including imbalance, looseness, resonance, and misalignment. By identifying these issues at the earliest stages, we help manufacturers avoid catastrophic damage. The goal of our vibration testing services in Detroit, MI, is simple: deliver clarity on machinery health and provide solutions that extend equipment life while reducing costs.

On-Site Industrial Field Balancing for Detroit Manufacturers

Balancing is one of the most effective methods for reducing machinery vibration and preventing breakdowns. Our industrial field balancing services enable us to correct imbalances directly on-site, without requiring the dismantling of equipment. This saves Detroit facilities time and money while ensuring smoother operation of motors, fans, blowers, and other rotating components.

Our dynamic and static balancing capabilities are designed to handle a wide range of applications, from large automotive assembly equipment to smaller precision machinery. Because we specialize in on-site field balancing in Detroit, manufacturers trust us to deliver immediate results that reduce vibration and restore equipment to peak performance.

Laser Alignment and Precision Engineering for Reliability

Another leading cause of vibration-related failures is shaft misalignment. When rotating shafts are not correctly aligned, machines experience excessive vibration, overheating, and premature wear. Our laser alignment services in Detroit correct these issues with pinpoint accuracy, improving efficiency and extending equipment life.

We integrate laser alignment as part of our vibration analysis services because it complements other predictive maintenance solutions. By providing precision alignment, we reduce strain on machinery, prevent bearing damage, and minimize the risk of costly downtime. Detroit manufacturers rely on us as both a mechanical engineering service provider and a predictive maintenance provider to ensure their operations remain reliable.

High-Speed Spindle Balancing and Motor Performance Optimization

High-speed spindles and motors are particularly susceptible to vibration issues. Even the slightest imbalance at high speeds can lead to poor product quality, reduced efficiency, and unexpected breakdowns. Our spindle balancing services are specifically tailored to the automotive and aerospace sectors in Detroit, where precision is crucial.

We also provide electric motor balancing and repair to optimize motor performance. By addressing vibration at its source, we extend motor life, reduce energy consumption, and improve overall system reliability. These services are not just about fixing immediate issues—they are about ensuring Detroit industries can count on their machinery day after day.

Predictive Maintenance and Condition Monitoring Programs in Detroit

While vibration analysis is highly effective on its own, it becomes even more powerful when combined with predictive maintenance and condition monitoring. At Dynamic Balancing Technologies, we offer long-term programs that track vibration data over time, identifying trends that reveal when a component is approaching failure.

Our condition monitoring services allow Detroit facilities to schedule maintenance at the right time, rather than reacting to emergencies. This proactive approach saves money, reduces stress on employees, and ensures machinery remains available when it is needed most. By implementing predictive maintenance programs that include vibration analysis, we help Detroit manufacturers build reliability into their operations.

Why Detroit Facilities Trust Dynamic Balancing Technologies

We have earned the trust of Detroit facilities by combining advanced technology with unmatched experience. With over 32 years of expertise in vibration analysis and dynamic balancing, we have developed a reputation for precision, reliability, and customer care. Our clients know that when they partner with us, they are working with a company that treats their equipment as if it were our own.

We also understand that emergencies do not follow a schedule. That is why we offer 24/7 vibration analysis and balancing services throughout Detroit, MI. When a facility experiences unexpected vibration issues, we respond promptly with the necessary tools and expertise to restore operations. This dedication to availability and excellence has established us as a trusted name in predictive maintenance and vibration analysis throughout the region.

Benefits of Professional Vibration Analysis for Detroit Manufacturers

The benefits of vibration analysis extend far beyond detecting faults. By investing in professional vibration analysis in Detroit, MI, manufacturers gain peace of mind knowing their equipment is monitored and maintained with precision. Our services reduce downtime, extend equipment lifespan, and improve workplace safety. They also lower maintenance costs by preventing failures that would require expensive emergency repairs.

Facilities that implement vibration analysis also experience improved efficiency. Machines that operate smoothly consume less energy and produce more consistent results. For Detroit manufacturers competing in demanding markets, this efficiency translates into real competitive advantages.

Service Reach of Dynamic Balancing Technologies Across Michigan

While Detroit is at the heart of our service area, we extend our vibration analysis and predictive maintenance services to nearby cities, including Warren, Sterling Heights, Dearborn, and Ann Arbor. Our coverage also includes Ohio, Indiana, Illinois, Kentucky, Pennsylvania, and Wisconsin, giving us a strong presence across the Midwest.

By providing both local expertise and regional availability, we ensure that manufacturers across multiple states can rely on us for on-site balancing, laser alignment, predictive maintenance, and vibration testing services. Our commitment to serving Detroit and beyond reinforces our role as a leading vibration analysis service provider in the Midwest.

Taking the First Step Toward Reliable Machinery in Detroit

Getting started with vibration analysis is straightforward. We begin with an equipment assessment that evaluates the condition of machinery and identifies potential risks. Once we collect vibration data, we provide detailed reports that highlight current performance, reveal potential failures, and recommend corrective actions.

Our approach is collaborative, ensuring Detroit manufacturers understand the results and have a clear plan for maintaining reliability. By partnering with Dynamic Balancing Technologies, facilities take the first step toward reducing costly machinery failures and building long-term operational confidence.

Frequently Asked Questions About Vibration Analysis in Detroit

How does vibration analysis help prevent costly equipment failures?

Vibration analysis detects small changes in machinery vibration patterns that indicate problems such as imbalance, misalignment, or bearing wear. By addressing these issues early, Detroit manufacturers can prevent breakdowns that lead to expensive repairs and downtime.

Can vibration analysis improve energy efficiency in Detroit facilities?

Yes. When machines are correctly balanced and aligned, they operate more efficiently and consume less energy. Our vibration analysis services help Detroit facilities reduce energy waste while improving equipment performance.

What makes Dynamic Balancing Technologies different from other providers?

Our company stands out because of our decades of experience, ISO-calibrated instruments, and 24/7 availability. We treat every client’s equipment with care and deliver detailed reports that provide actionable insights, making us a trusted provider of vibration analysis services in Detroit.

Do you offer vibration analysis for automotive plants in Detroit?

Absolutely. Detroit’s automotive industry depends heavily on rotating equipment, and we specialize in providing vibration analysis, balancing, and predictive maintenance services for automotive plants. Our expertise ensures equipment reliability in one of the most demanding industries.

Is vibration analysis a one-time service or an ongoing program?

While vibration analysis can be performed as a one-time service, it is most effective when integrated into an ongoing predictive maintenance program—our condition monitoring services in Detroit track vibration data over time, providing continuous protection against unexpected failures.

Conclusion: Preventing Failures with Trusted Vibration Analysis in Detroit

Machinery failures are expensive, disruptive, and avoidable. With vibration analysis in Detroit, MI, manufacturers have a powerful tool to prevent costly breakdowns and maintain smooth operations. At Dynamic Balancing Technologies, we provide the expertise, technology, and dedication required to keep Detroit industries running efficiently.

From field balancing and laser alignment to predictive maintenance and condition monitoring, our services are designed to protect equipment and extend its life. Detroit facilities continue to trust us because we combine decades of experience with a relentless commitment to customer success. When it comes to preventing machinery failures, vibration analysis is the solution, and Dynamic Balancing Technologies is the trusted partner.