Machine diagnostics powered by vibration analysis help detect imbalance, misalignment, looseness, or bearing faults early Early warnings translate into longer equipment life and fewer disruptions Expensive repairs, unplanned shutdowns, and safety risks follow unchecked faults You build confidence in scheduling repairs before things go wrong The ripple effect benefits quality, energy use, and safety across operations

Common Faults Found via Vibration Testing

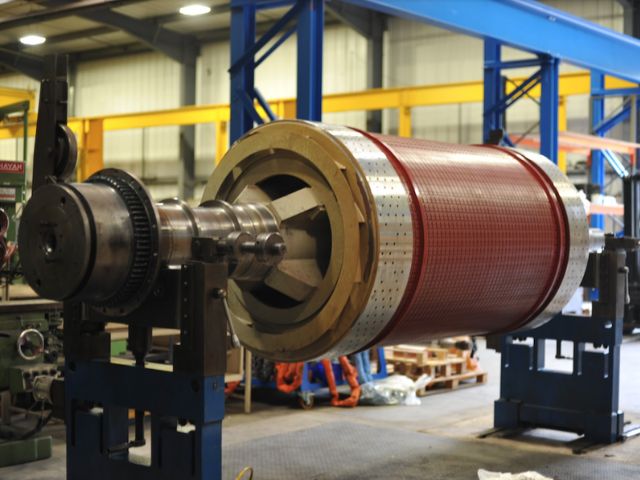

One frequent issue is rotor imbalance—tiny weight offsets create significant vibration and bearing stress Misalignment is also common, often from setup drift or coupling wear These faults often precede total bearing failure Vibration diagnostics reveal these behavior patterns Together, identifying imbalance, misalignment, looseness, and bearing faults leads to successful corrective actions

How Vibration Diagnostics Fits Into Maintenance Strategy

Rather than fixed intervals, you perform work when trending data indicates it’s needed This minimizes unnecessary maintenance and avoids surprise breakdowns Your operational rhythm stabilizes You calibrate maintenance intervals dynamically You operate more reliably with fewer surprises

Full Suite of Machine Health Services

At Dynamic Balancing Technologies, vibration testing is one pillar in a broader diagnostics and balancing offering Dynamic balancing corrects imbalance under rotation; static balancing ensures weight symmetry when stationary This saves downtime and preserves alignment Additional services include precision motor balancing, industrial fan balancing, and calibration of test systems You don’t just get reports—you get solutions

Why Choose Dynamic Balancing Technologies in Grand Rapids

We bring Dynamic Balancing Technologies both technical prowess and practical insight to each project We deliver reports tailored to your equipment and goals Maintenance teams can act immediately without guessing We support emergency balancing and unscheduled diagnostics when machines falter Choosing us means partnering with a team committed to safeguarding your capital assets and maximizing uptime

Scheduling Guidance for Vibration Analysis

Temperature rises, unusual noise, or performance loss are signals High-speed or continuously running equipment may 1businessworld.com need more frequent checks You gain confidence in machinery integrity We advise clients in Grand Rapids to schedule diagnostics proactively rather than reactively When vibration trends climb above your threshold, engage us quickly

Frequently Asked Questions

How does vibration testing improve machine diagnostics?

Vibration testing measures subtle movement, velocity, and acceleration to reveal faults like imbalance, misalignment, or bearing wear

What types of equipment benefit from vibration testing?

Even smaller devices can show early faults

How often should vibration testing be scheduled?

You tailor frequency based on trends

Are emergency vibration analyses available?

Yes, we provide 24/7 emergency vibration testing and field balancing in Grand Rapids and beyond

Which standards guide your vibration diagnostics process?

You receive results aligned with industry best practice

Conclusion: Partner with Dynamic Balancing Technologies for Machine Health

Investing in professional vibration testing is not a luxury—it’s a necessary pillar in maintaining industrial performance We tailor solutions to equipment types, operating conditions, and business objectives By combining vibration testing with balancing services and predictive maintenance, you build a resilient system Call us or email to begin optimizing your machinery with data‑driven clarity