Industrial field balancing plays a vital role in maintaining the performance and longevity of rotating machinery throughout Detroit manufacturing facilities. At Dynamic Balancing Technologies, we deliver professional on-site balancing services that eliminate harmful vibrations without requiring equipment removal from your plant. Our expert technicians bring advanced vibration analysis capabilities directly to your location, diagnosing rotor imbalance issues and applying precise corrections while machinery remains installed. This essential maintenance approach protects your important rotating equipment investment and reduces unexpected downtime substantially. Your Detroit plant can achieve optimal operational efficiency during high-demand production periods with our expertise. Trust our team to deliver reliable balancing solutions that keep your machinery running smoothly.

Understanding the Critical Role of On-Site Balancing for Industrial Equipment

Field balancing has become an indispensable service for industrial facilities seeking to maintain rotating equipment reliability without sacrificing valuable production time. We bring complete balancing solutions to your location, reducing interference with your production schedule. The capability to perform precision balancing work while equipment remains installed offers substantial advantages over traditional shop methods. Production activities can continue with minimal delay following our on-site service. Our team recognizes that production interruptions directly impact your bottom line, so we optimize our services for speed and effectiveness. Dynamic Balancing Technologies remains committed to providing responsive service that meets the demanding schedules of Detroit area manufacturers.

The Key Differences Between On-Site and Shop-Based Balancing Approaches

Traditional shop balancing requires disassembling rotating components, transporting them off-site, and reinstalling after correction, which creates extended downtime and risks damage during handling. On-site balancing removes these issues since all service happens right at your facility. We balance complete assembled machines under genuine operating conditions, capturing assembly tolerances and environmental factors that shop methods fail to address. Our methodology produces better outcomes while significantly cutting the time your machinery sits idle. Machinery gets precision corrections under true operational parameters rather than simulated shop environments. Contact Dynamic Balancing Technologies today to experience the advantages of professional field google.com balancing services.

Using Vibration Analysis to Detect Concealed Rotor Imbalance Problems

Vibration analysis serves as our principal diagnostic tool for identifying imbalance conditions in rotating machinery with exceptional accuracy. We attach precision sensors to bearing housings and collect comprehensive measurements at operating speed to capture the full picture of your equipment condition. Our state-of-the-art equipment analyzes vibration amplitude, frequency content, and phase relationships to pinpoint imbalance locations accurately. Our analytical methodology uncovers concealed issues before they lead to major breakdowns, safeguarding your machinery. Precise adjustments resolve fundamental issues instead of merely treating surface-level equipment symptoms. The diagnostic services we provide enable durable repairs that enhance machinery dependability over extended periods.

Understanding the Relationship Between Good Balance and Machinery Reliability

Properly balanced rotating machinery experiences significantly reduced stress on bearings, seals, couplings, and supporting structures. Lower vibration levels mean less mechanical wear and longer component service life, which converts to reduced maintenance costs over time. Equipment reliability improves dramatically when imbalance forces are eliminated, resulting in fewer unexpected breakdowns and more predictable maintenance intervals. The on-site balancing we provide creates the basis for reliable machinery function that Detroit industrial facilities need for steady production results. Investing in professional balancing services today prevents costly repairs and production losses tomorrow. We support your efforts to attain the equipment consistency your manufacturing process needs.

Frequent Rotating Machinery Issues Affecting Detroit Area Manufacturing Operations

Detroit’s manufacturing sector operates some of the most demanding rotating equipment applications in American industry, with automotive suppliers running production machinery continuously across multiple shifts. Metal processing facilities operate heavy machinery at peak levels, generating demanding circumstances that speed up deterioration patterns causing emerging balance issues. Material buildup on fan blades, erosion of pump impellers, and thermal distortion of motor armatures all lead to vibration problems that worsen progressively without intervention. Production plants spanning the greater Detroit region deal with issues from aging equipment that has run for many years without appropriate balancing service. Repair welding, component replacements, and normal wear patterns modify the original mass distribution of rotating parts over time. Our technicians frequently find machinery that has operated for extended periods without expert balancing while harmful vibration levels deteriorate associated parts.

The Dangers Unbalanced Machinery Poses to Productivity and Worker Safety

Unbalanced rotating machinery significantly affects production efficiency through multiple mechanisms that compound over time, creating increasingly severe operational challenges. Excessive vibration causes accelerated bearing wear, leading to more frequent replacements and associated downtime that disrupts production schedules. Compromised seals enable lubricant escape and foreign material intrusion that further damage equipment status. Motors driving unbalanced loads consume more electrical energy while delivering reduced output, elevating operating costs while decreasing productive capacity throughout affected production lines. Employee safety risks develop when rotating equipment functions with considerable imbalance situations, because vibrating machinery can work fasteners loose and potentially lead to dangerous failures putting workers at risk. Resolving imbalance via professional mobile balancing preserves both equipment value and personnel safety throughout your Detroit plant.

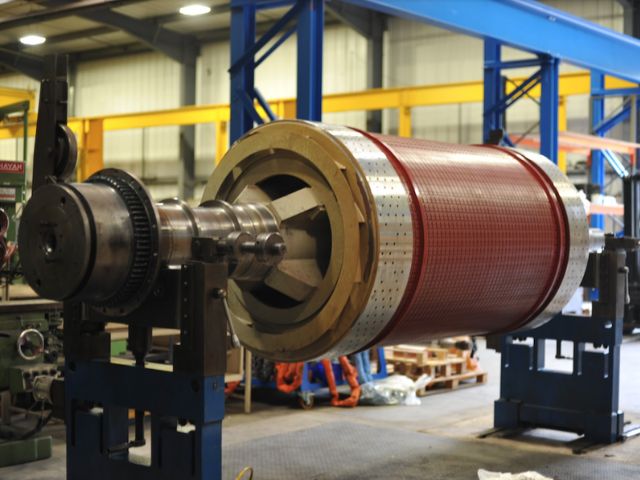

Critical Rotating Machinery Needing Expert Balancing Attention

Our mobile balancing services address vibration problems across all categories of rotating equipment found in Michigan industrial facilities with remarkable precision. We provide targeted experience and precise diagnostic equipment for all rotating machinery requiring professional care. From minor precision components to massive industrial assemblies, our technicians have the skills and equipment necessary to restore proper balance. The extensive range of our expertise means nearly all rotating machinery at your plant can receive our professional attention. Our team recognizes the specific needs of various machinery categories and uses suitable methods for best outcomes. Reach out to our team to talk about your particular machinery balancing requirements.

Industrial Ventilation Fans, Blowers, and Air Handling Equipment

Industrial fans and blowers represent some of the most common field balancing applications in manufacturing environments due to their essential role in facility operations. Dust collection systems, exhaust fans, and HVAC air handling units develop imbalance from material accumulation, blade erosion, and component wear over their service life. We balance centrifugal fans, axial fans, and blower wheels across the full range of sizes found in Detroit facilities. Our on-site approach restores smooth operation quickly, maintaining air quality and environmental compliance without extended equipment removal. Properly balanced fans operate more quietly, consume less energy, and last significantly longer than imbalanced units. Rely on our team for complete industrial fan balancing services.

Industrial Motors, Pump Systems, and Compressor Equipment

Electric motors and pumps power vital production processes throughout Detroit manufacturing plants, making their reliable operation absolutely essential. Imbalance in motor armatures or pump impellers creates vibration that propagates through entire drive trains, influencing connected equipment and accelerating component wear across multiple systems. On-site balancing procedures address these issues with machinery in place, maintaining shaft alignment and reducing reinstallation requirements. Compressor units similarly benefit from on-site balancing that addresses imbalance under actual operating pressures and temperatures for best results. The precision corrections we provide extend equipment service life while improving operational efficiency. Get in touch to book motor, pump, or compressor balancing services for your operation.

High-Precision Spindles and Fast-Rotating Drive Shafts

Machine tool spindles and high-speed drive shafts demand superior balance quality to maintain precision requirements that modern manufacturing operations depend upon. Slight imbalance conditions at fast rotation rates produce considerable vibration forces that diminish machining accuracy and finish quality. Our technicians focus in balancing precision components to extremely tight tolerances meeting ISO 1940 standards for challenging applications. We service needs for aerospace, automotive, and precision manufacturing operations where balance precision directly influences product precision. Fast-rotating component balancing demands specific expertise and instrumentation that our skilled professionals have. Trust Dynamic Balancing Technologies for your most demanding spindle and drive shaft balancing requirements.

How Regular Vibration Monitoring Supports Predictive Maintenance Success

Predictive maintenance programs incorporating regular vibration monitoring provide Detroit manufacturers with powerful tools for optimizing equipment reliability and maintenance spending across their operations. Rather than following calendar-based maintenance schedules that may perform unnecessary work or miss developing problems, vibration monitoring identifies actual equipment condition. Our predictive maintenance services establish baseline vibration measurements for critical rotating machinery, then track changes over time to detect emerging imbalance conditions before they cause substantial damage. Regular monitoring allows maintenance teams to plan balancing interventions at convenient times rather than responding to emergency breakdowns. This proactive approach extends equipment service life, reduces spare parts consumption, and virtually eliminates unplanned downtime from imbalance-related failures. Dynamic Balancing Technologies offers monitoring programs with quarterly, biannual, or annual intervals adapted to your equipment criticality and operating conditions.

Sectors Throughout Greater Detroit Gaining from On-Site Balancing Services

Dynamic Balancing Technologies serves varied industries throughout Metro Detroit, Macomb County, Wayne County, and Oakland County with professional field balancing services designed to meet specific industry demands. Vehicle manufacturing facilities and their broad supply chain partners depend on our knowledge when production machinery experiences vibration issues needing prompt service. Steel processing facilities rely on our capabilities with heavy rotating components operating under extreme conditions that require specialized expertise. Power generation stations count on our precision balancing for turbines and generators where reliability directly impacts regional electrical supply to countless customers. Our mobile balancing solutions also serve aerospace manufacturing operations requiring exceptional balance quality for flight-critical components. Pulp and paper operations, food production facilities, chemical processing plants, pharmaceutical manufacturers, and medical institutions all gain from our mobile methodology that reduces interference while providing expert outcomes addressing their particular sector needs.

Critical Criteria for Picking a Trustworthy Field Balancing Company in Michigan

Choosing the right field balancing provider ensures your rotating equipment receives expert attention delivering durable results that protect your investment. Multiple important considerations separate competent balancing providers from inferior options available across Michigan. Understanding these factors helps you make informed decisions that benefit your operation https://www.youtube.com/@dynamicbalancingtechnologiesll for years to come. The expertise, responsiveness, and technical capabilities of your balancing partner directly impact the quality of results you receive. Invest effort in assessing prospective providers completely before establishing a service arrangement. Dynamic Balancing Technologies welcomes the opportunity to demonstrate our qualifications.

Experience and Technical Expertise in Diverse Applications

Field balancing expertise develops through years of hands-on experience across varied equipment types and commercial applications that cannot be rushed or shortcut. Seek companies showing established abilities with equipment comparable to your particular machinery. Ask about experience with your sector and the particular challenges your equipment presents to ensure compatibility with your needs. Our team brings over 33 years of accumulated expertise balancing everything from small precision spindles to massive industrial fans, developing deep knowledge applicable across diverse situations. This extensive background allows us to quickly diagnose problems and implement effective solutions for virtually any rotating equipment challenge. Choose Dynamic Balancing Technologies for expertise you can trust.

Emergency Response Capability and Service Area Coverage

Equipment failures infrequently occur at convenient times, making emergency response capability vital for critical production machinery that cannot afford extended downtime. Ensure prospective providers deliver quick response for emergency circumstances and validate their coverage area includes your plant location. We offer 24/7 emergency mobile balancing services spanning Southeast Michigan and provide countrywide coverage when vital equipment needs immediate professional service regardless fan balancing services Michigan of geographic location. Our rapid response capabilities have helped countless Detroit area manufacturers avoid costly production losses. When your equipment malfunctions, you need a company that can come rapidly and solve problems proficiently. Trust Dynamic Balancing Technologies for emergency balancing services when timing is critical.

State-of-the-Art Diagnostic Tools and Professional Certifications

Professional field balancing requires sophisticated vibration analysis equipment capable of accurate measurements across the full range of machinery speeds and configurations found in industrial settings. Competent companies purchase modern equipment and preserve calibration standards guaranteeing dependable outcomes you can depend upon. Industry certifications and ongoing training demonstrate commitment to professional development and expert competence in the field. Our team utilizes state-of-the-art diagnostic instrumentation and follows established standards for balance quality verification. We consistently enhance our technology and knowledge to ensure our competencies remain among the best in the industry. Our company sustains the analytical abilities and expert standards your machinery requires.

How Dynamic Balancing Technologies Differs from Competitors in Southeast Michigan

Dynamic Balancing Technologies has established our reputation as Southeast Michigan’s dependable field balancing partner through unwavering commitment to customer service and technical excellence that clients recognize. Founded in 2020 and headquartered in Macomb Township, we combine entrepreneurial responsiveness with over 33 years of industry experience accumulated by our skilled technicians. This special combination allows us to deliver personalized attention while applying proven expertise to your specific equipment challenges effectively. Our approach emphasizes open communication and consultation throughout every project. We work closely with your maintenance personnel to understand unique requirements and develop cost-effective solutions tailored to your operational needs. Whether you require baseline vibration analysis, monthly monitoring programs, or emergency response for unexpected breakdowns, our team delivers professional results that protect your equipment investment.

Common Questions Regarding Industrial Rotating Machinery Balancing

How Does Field Balancing Compare to Traditional Shop Balancing Methods?

Mobile balancing avoids costly dismantling, transport, and reinstallation while accounting for real working conditions shop approaches cannot duplicate. We balance complete assembled machines accounting for assembly tolerances, mounting effects, and environmental factors that impact equipment performance. Machinery resumes operation in hours instead of days, maintaining production output and lowering overall maintenance expenses.

How Can I Tell When My Rotating Equipment Requires Professional Balancing?

Excessive vibration felt on machine housings, unusual rumbling or cyclical noises, loosening fasteners, and premature bearing failures all indicate potential imbalance conditions. Increased power consumption, visible shaft movement, and declining product quality from vibration-affected processes furthermore signal developing problems. These indicators need professional vibration analysis and balancing intervention to prevent continued equipment damage.

How Can Vibration Analysis Identify Equipment Issues Before They Worsen?

Vibration analysis measures amplitude, frequency, and phase characteristics that reveal specific mechanical conditions including imbalance, misalignment, and bearing wear. By establishing baseline measurements and monitoring trends, we identify developing problems before catastrophic failure occurs in your essential equipment. Prompt identification enables scheduled repairs reducing production interference and avoiding collateral damage to associated parts.

Is It Possible to Balance Equipment While Nearby Machinery Continues Running?

In numerous circumstances, we can service specific machines while neighboring equipment keeps running normally without major disruption. Specific circumstances depend on your facility layout, safety requirements, and vibration isolation between machines in your plant. We collaborate with your personnel to determine best scheduling that reduces production effects while maintaining safe circumstances for our professionals.

What Industries Benefit Most from Professional Field Balancing Services?

All industries utilizing rotating machinery benefit from professional field balancing services, including automotive manufacturing, steel processing, power generation, aerospace, and paper production. Food processing, chemical manufacturing, pharmaceutical operations, and HVAC applications furthermore rely on balanced rotating equipment for optimal performance. Any facility where equipment reliability impacts production output or safety benefits from our professional balancing expertise.

Preserve Your Rotating Machinery Investment Using Professional On-Site Balancing

Expert field balancing from Dynamic Balancing Technologies offers vital protection for rotating machinery throughout Detroit region manufacturing plants. Our https://www.pinterest.com/rachelmcgrew17/_profile/ expert technicians, advanced diagnostic capabilities, and commitment to responsive service ensure your vibration problems receive expert attention with minimal operational disruption. We appreciate establishing enduring partnerships with Detroit area manufacturers who count on rotating equipment reliability. Whether your facility requires ongoing predictive maintenance monitoring or immediate emergency response for critical equipment failures, we provide professional solutions safeguarding your equipment investment. Get in touch with Dynamic Balancing Technologies today to learn how our mobile balancing services can support your Detroit manufacturing plant. We anticipate helping your production operate smoothly and your machinery function at peak performance.