At Dynamic Balancing Technologies, we believe that maintaining the efficiency and longevity of your rotating equipment shouldn’t come at an overwhelming cost. That’s why we proudly offer affordable dynamic balancing solutions in Detroit and the surrounding areas. With over 32 years of experience and a commitment to precision, our team is dedicated to ensuring your machinery operates smoothly, safely, and with minimal downtime. Whether you operate in manufacturing, aerospace, automotive, or energy, we understand the importance of properly balanced rotating components to your daily operations.

Why Choose Dynamic Balancing Technologies in Detroit, MI?

Our reputation as a trusted partner in machinery diagnostics and repair is built on decades of hands-on expertise, technical accuracy, and unmatched customer service. Located in Romeo, MI, we serve clients throughout Detroit and the Midwest, including Illinois, Indiana, Ohio, and Wisconsin. Clients turn to us not just for our capabilities but for our commitment to extending the life of their equipment while minimizing unexpected maintenance costs. We work closely with a wide range of industries, including food processing, healthcare, pulp and paper, and defense. Regardless of the machinery’s complexity, our precision balancing techniques help maintain optimal performance.

What is Dynamic Balancing and Why is it Essential for Rotating Equipment?

Dynamic balancing is a crucial service that ensures rotating equipment operates smoothly without generating excessive vibration. Over time, even the most precisely manufactured parts can become unbalanced due to wear, material inconsistencies, or assembly errors. This imbalance can lead to excessive vibration, mechanical failure, and safety risks. At Dynamic Balancing Technologies, we utilize advanced balancing machines and field equipment to identify these issues and implement fine-tuned corrections that restore equilibrium.

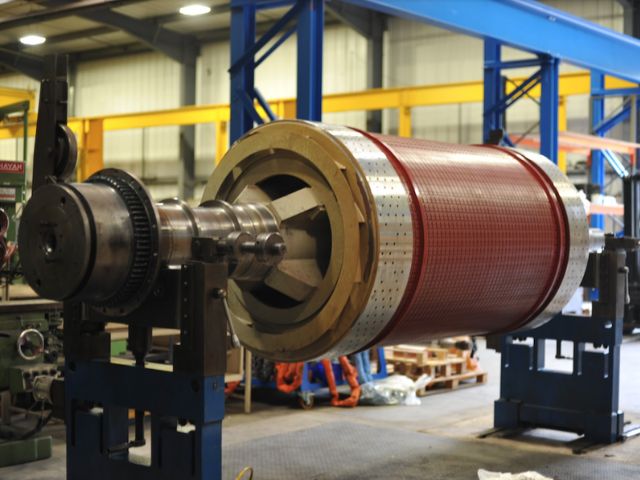

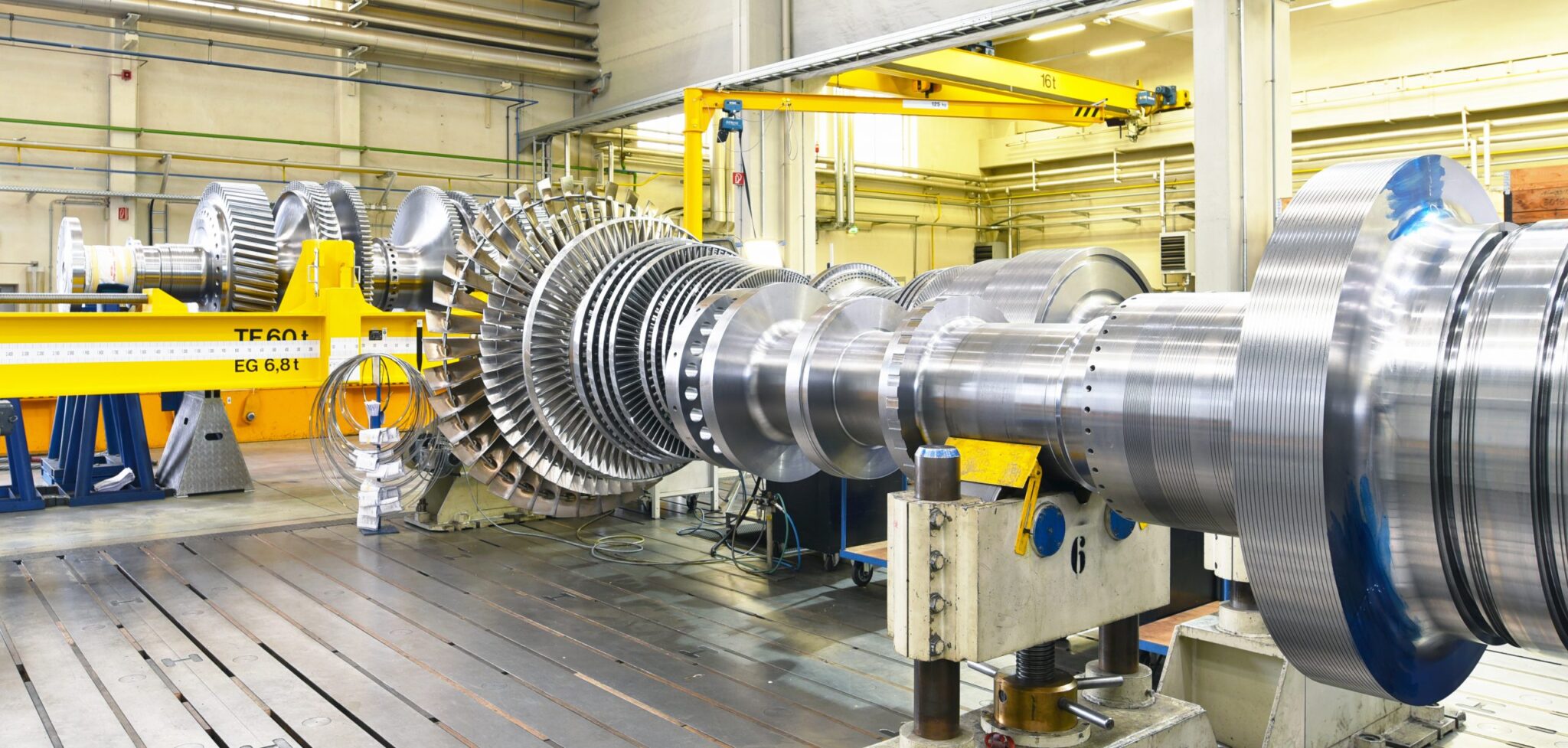

When a component such as a fan, impeller, rotor, or shaft spins, any deviation in its mass distribution creates a centrifugal force. That force translates to vibration, which stresses bearings, shortens equipment life, and reduces operational efficiency. By performing dynamic balancing, we correct the distribution of mass so that the center of gravity aligns with the axis of rotation. This not only enhances safety and performance but also lowers energy consumption and increases uptime.

Our Full-Service Capabilities for Industrial Equipment in Detroit

Dynamic Balancing Services for Industrial Rotating Equipment

Dynamic Balancing Technologies offers comprehensive services tailored to industrial rotating equipment of all sizes and functions. We support both in-shop and on-site dynamic balancing for components weighing up to 250 pounds. From electric motors and fans to pulleys and shafts, our team ensures every piece of machinery is balanced to meet or exceed ISO 1940 standards. These services are critical in extending the service life of high-speed equipment and improving production line reliability.

Static Balancing Services for Precise Mass Correction

In addition to dynamic balancing, we provide expert static balancing services. While dynamic balancing focuses on parts in motion, static balancing addresses mass imbalances in stationary components. This is ideal for parts like flywheels or slower-moving machinery. When an item rolls to a heavy spot, it’s a clear sign that static balancing is needed. Using single-plane corrections, we eliminate these imbalances, preventing wear and improving machine stability.

In-Field Dynamic Balancing for On-Site Equipment Repairs

For businesses in Detroit seeking to eliminate the hassle of transporting heavy machinery, our field balancing services provide the ideal solution. Our technicians visit your site directly, equipped with portable instruments that measure vibration and identify unbalanced conditions in real-time. We then apply counterweights or material adjustments on-site to bring the machine back into balance. This reduces downtime and maintains your productivity without sacrificing accuracy.

Vibration Analysis Services to Diagnose Machine Health

Our vibration analysis services complement dynamic balancing. Before performing any balancing procedures, we typically conduct a comprehensive vibration analysis to identify the root cause of the issue. This analysis includes measurements such as velocity, acceleration, and frequency spectra. Based on the results, we recommend whether balancing, alignment, or other corrective actions are required. This preventive approach not only saves money but ensures machinery health is proactively managed.

Laser Shaft Alignment Services for High-Speed Machines

We also offer precise laser shaft alignment services for high-speed and interconnected machinery. Misaligned shafts can quickly cause wear on bearings, couplings, and seals. Our laser alignment tools correct these issues with micron-level precision, ensuring that motors and driven equipment remain perfectly aligned. This is especially useful for HVAC systems, pumps, gearboxes, and compressors found throughout Detroit’s industrial facilities.

Balancing for Fans, Blowers, and Electric Motors

In environments where airflow and motor efficiency are crucial, such as HVAC or energy systems, we provide targeted balancing for fans, blowers, and electric motors. An unbalanced fan not only increases noise but can severely reduce airflow efficiency. By balancing these components, we help you achieve optimal performance, reduce energy costs, and extend the life of your motors. We service everything from axial fans to centrifugal blowers used in commercial and industrial settings.

Balancing Services for CNC and Spindle Tooling

For manufacturing facilities and machine shops using CNC and spindle tooling, high-precision balancing is a necessity. Our technicians specialize in spindle balancing that minimizes runout and tool wear, ensuring cleaner cuts and more accurate machining. This is particularly beneficial in the automotive and aerospace sectors where tolerances are extremely tight and equipment vibration can lead to expensive rework.

Industries Served Across Detroit and the Midwest

A wide array of industries throughout Detroit and the surrounding Midwest trusts our balancing services. We serve automotive manufacturers that rely on precise rotating components for assembly lines, as well as aerospace firms where tight tolerances and vibration-free environments are non-negotiable. Defense contractors, healthcare facilities, and energy producers also depend on our balancing solutions to maintain operational reliability. Food processing and paper mills, which require continuous production, rely on us for on-site balancing and vibration analysis to prevent costly downtime. Our ability to customize services for each industry ensures that clients always receive what they need, when they need it.

Our Process: How We Deliver Reliable Dynamic Balancing Results

From the moment you reach out to us, our goal is to deliver efficient, accurate, and affordable solutions. We begin every project with an initial inspection that includes a visual assessment and a review of the equipment’s history. From there, we gather real-time vibration data to diagnose the exact issue. Once we identify the cause of imbalance, our technicians use dynamic balancing machines or portable field equipment to make the necessary corrections.

After balancing is completed, we generate a detailed report outlining the before-and-after vibration readings, what corrections were made, and maintenance recommendations to prevent future issues. This process not only addresses immediate concerns but also lays the foundation for a comprehensive long-term equipment health strategy. Clients appreciate our transparency, professionalism, and ongoing support, knowing that our job isn’t finished until their machinery is running smoothly again.

Serving Detroit and Surrounding Areas with Affordable Precision

We are proud to offer cost-effective dynamic balancing solutions to clients throughout Detroit and beyond. Our affordable pricing structure is designed to make top-tier balancing services accessible to businesses of all sizes. Whether you operate a local manufacturing plant or a regional processing facility, we offer flexible service packages that meet your budget without compromising quality.

We also provide emergency balancing services across the United States, meaning that even if you’re outside Michigan, you can count on us when it matters most. Our combination of affordability, accuracy, and responsive service has made us a preferred partner for clients seeking long-term reliability in their rotating machinery.

Frequently Asked Questions (FAQ)

What is the difference between dynamic and static balancing?

Dynamic balancing is performed while the part is in motion, correcting imbalances that occur during operation. Static balancing is done while the part is stationary and addresses single-plane imbalances. Both are important, and we offer expert services for each based on your specific needs.

How do I know if my equipment needs balancing?

If your machinery is vibrating, making excessive noise, or showing uneven wear on bearings and seals, it may be out of balance. Our vibration analysis services help identify the root cause, enabling us to recommend the most suitable solution.

Do you offer on-site balancing services in Detroit?

Yes, we offer industrial field balancing services throughout Detroit and the Midwest. Our technicians bring all necessary equipment to your facility and complete the work on-site, minimizing disruptions.

What industries do you serve?

We work with clients across various industries, including automotive, aerospace, healthcare, energy, food processing, and more. If your industry involves rotating machinery, we have the expertise to support your maintenance needs.

What’s included in your vibration analysis report?

Our reports provide detailed information on vibration velocity, frequency, and acceleration. They also include before-and-after balancing results, diagnosis, and actionable maintenance recommendations to ensure the long-term health of the machinery.

Contact Dynamic Balancing Technologies for Detroit’s Most Trusted Machinery Balancing

When it comes to balancing rotating machinery, no one offers the same level of experience, precision, and affordability as Dynamic Balancing Technologies. We’re not just a service provider—we’re your maintenance partner. If your equipment is showing signs of vibration, wear, or performance drop-offs, don’t wait for a failure. Reach out today and let us help you restore balance to your operations.

Address: 295 North Main Street, Romeo, MI 48065

Phone: (586) 280-8256

Email: dynamicbalancingtech@gmail.com