- Homepage

- Electric Motor Repair

Electric Motor Repair Sales and Service

Inspections from 1 unit up to 200 units. Programs available quarterly, biannually, or annually. We help minimize costly downtime and catch service issues before they become problems.

Overview

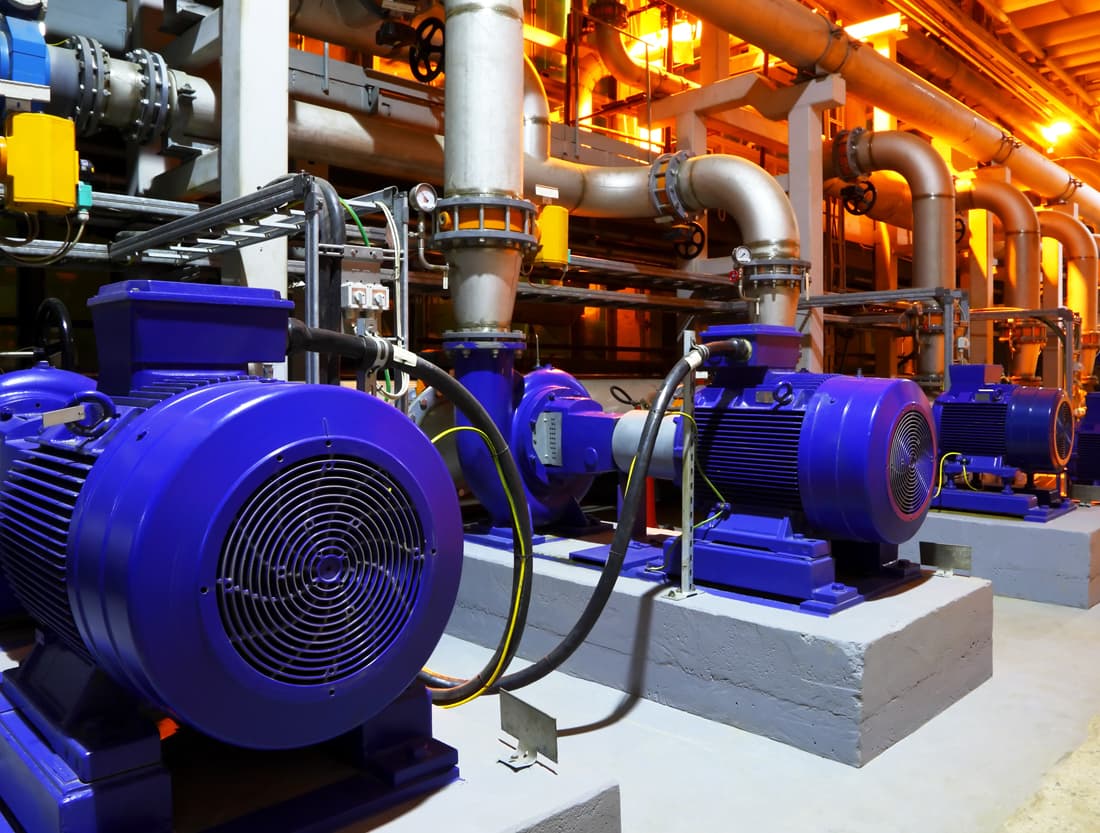

Rotating Apparatus Repair

We provide complete repair capabilities for all rotating apparatus equipment including A/C and D/C electric motors, gear reducers, industrial pumps, and blowers. Our inspection programs are available quarterly, biannually, or annually—servicing from 1 unit up to 200 units and ranging from 5HP to 500HP.

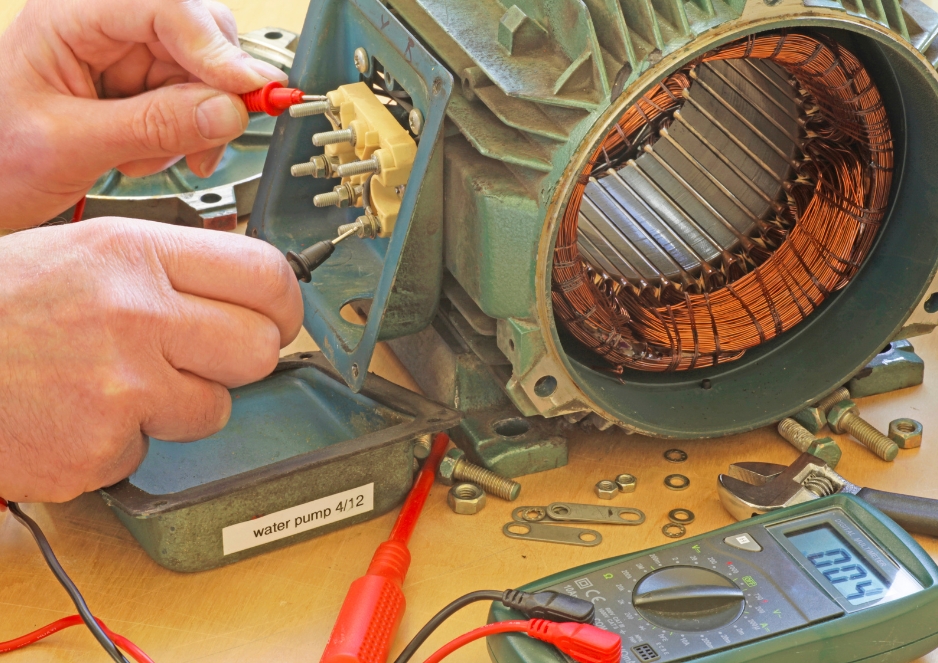

Our team works closely with maintenance departments to assess service needs, minimize downtime, and detect costly issues before they escalate. We offer onsite preventative maintenance programs, including electrical checks such as amps/ohms, insulation, meg checks, brush wear, and communicator condition. Bearing inspections, contamination detection, and thermal imaging are included in our detailed diagnostics.

Our team works closely with maintenance departments to assess service needs, minimize downtime, and detect costly issues before they escalate. We offer onsite preventative maintenance programs, including electrical checks such as amps/ohms, insulation, meg checks, brush wear, and communicator condition. Bearing inspections, contamination detection, and thermal imaging are included in our detailed diagnostics.

Overview

Motor Field Testing

We assess each unit in collaboration with the maintenance department, helping plan service needs and minimize downtime. Our inspections range from single units up to 200, with repair capability from 5HP to 500HP. We perform electrical diagnostics such as amps, ohms, meg checks, and insulation evaluation. For D/C equipment, we check brush wear and communicator condition. Bearing condition and contamination issues are also addressed. Our preventative maintenance programs ensure early detection of issues. Thermal imaging is available onsite to verify system health and performance, helping extend equipment life and ensure safe operation of rotating apparatus systems.