When rotating equipment fails unexpectedly, every minute of downtime costs Detroit manufacturers significant revenue and threatens production schedules. Dynamic Balancing Technologies provides emergency industrial field balancing services with rapid response capabilities designed for situations where production cannot wait. Our experienced technicians mobilize quickly to diagnose vibration problems and restore equipment operation at your facility, eliminating the delays associated with equipment removal and off-site repairs. We understand that critical machinery failures demand immediate professional attention, which is why we offer 24-hour emergency on-site balancing services throughout Metro Detroit and Southeast Michigan.

Understanding Emergency Field Balancing and Why Immediate Response Matters

Emergency field balancing addresses critical failures in rotating equipment that require immediate professional intervention to restore production operations. Our rapid response services help Detroit manufacturers minimize costly downtime.

What Constitutes an Emergency Balancing Situation

Emergency balancing situations arise when critical rotating equipment develops severe vibration preventing safe or effective operation. Sudden onset of excessive shaking, unusual noises indicating imminent bearing failure, or equipment shutdowns from vibration alarms all constitute emergencies. Production line stoppages that affect downstream operations and safety concerns from violently vibrating machinery require an immediate professional response. Our emergency services address these urgent situations promptly.

The Cost of Production Downtime in Detroit Manufacturing

Detroit manufacturing facilities face substantial financial impact during unplanned equipment downtime. Automotive suppliers operating on a just-in-time production model risk contractual penalties when deliveries fail. Continuous process operations lose product and revenue every hour equipment remains offline. Labor costs continue while production stops. Secondary effects including customer relationship damage and expedited shipping expenses compound direct losses. These accumulated costs make rapid response essential.

How Rapid Response Minimizes Operational Losses

Rapid emergency response dramatically reduces total downtime compared with standard service scheduling or equipment replacement. Our technicians arrive quickly with complete diagnostic and correction capabilities ready for immediate deployment. On-site balancing eliminates transportation delays inherent in shop repair options. Equipment typically returns to service within hours rather than days, preserving production capacity and protecting revenue. Fast response contains problems before secondary damage escalates.

When Your Rotating Equipment Fails Without Warning

Rotating equipment failures often occur without warning despite appearing to operate normally beforehand. Sudden imbalance can result from component failures, material release, or accumulated wear that reaches critical thresholds. Blade losses on fans, coupling failures, and bearing seizures can cause immediate, severe vibration. Equipment operating near resonance frequencies may suddenly exceed acceptable limits from minor changes. These unexpected failures require emergency response capabilities to restore operations quickly.

Manufacturing facilities depending on critical rotating equipment face significant vulnerability to sudden failures disrupting operations. Single points of failure in ventilation systems, cooling operations, or material handling can halt entire production lines. Equipment redundancy helps but cannot eliminate all failure risks. When critical machinery fails unexpectedly, having a reliable emergency field balancing partner already identified enables faster response. Our team stands ready to respond when Detroit area manufacturers experience urgent rotating equipment problems requiring immediate professional attention.

Our 24-Hour Emergency Field Balancing Process

Our emergency response process begins immediately upon receiving your call for urgent assistance. We gather essential information about your equipment situation, location, and access requirements while mobilizing our nearest available technician. Our emergency response vehicles carry complete vibration analysis equipment, balancing instrumentation, and correction materials needed for most situations. We coordinate arrival timing with your facility personnel to ensure immediate access upon reaching your location.

Upon arrival, our technicians conduct rapid diagnostic assessment to confirm imbalance as the primary problem and identify any additional conditions requiring attention. We collect vibration measurements, perform trial weight calculations, and execute correction procedures efficiently without sacrificing accuracy. Our experience across thousands of balancing jobs enables quick yet precise work under emergency conditions. Following permanent corrections, we verify results with final measurements confirming successful restoration before returning equipment to your operations team.

Critical Equipment We Service During Emergency Calls

Our emergency field balancing services address critical rotating equipment failures across all categories found in Detroit manufacturing facilities. We respond rapidly with expertise applicable to diverse machinery types.

Industrial Fans, Blowers, and Ventilation Systems

Industrial fans and ventilation systems frequently require emergency balancing when sudden failures threaten production or safety. Exhaust systems maintaining air quality, dust collection preventing explosion hazards, and cooling fans protecting heat-sensitive processes all demand immediate restoration when failures occur. We balance centrifugal fans, axial fans, and blower wheels during emergency calls, restoring critical airflow quickly. Our portable equipment handles fan emergencies from small units to large installations.

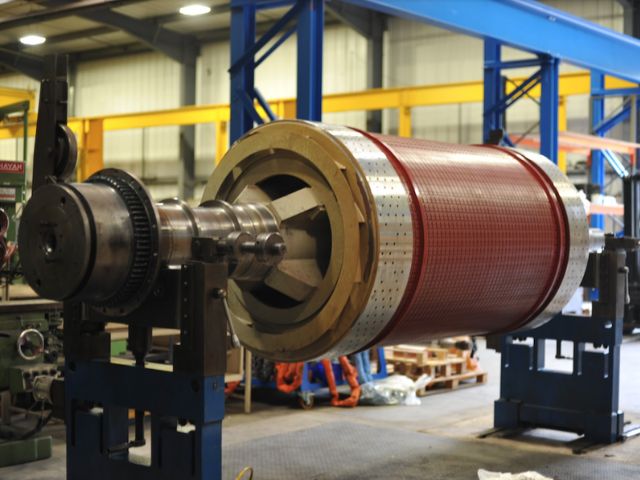

Electric Motors, Pumps, and Critical Drive Components

Electric motors and pumps powering essential processes often require emergency attention when unexpected vibration develops. Production line drives, cooling water pumps, and hydraulic system motors represent critical assets where failures halt operations immediately. Our emergency services address motor armature imbalance, pump impeller problems, and drive component issues on-site. We restore these essential systems rapidly, minimizing production interruption and preventing secondary damage to connected equipment components.

High-Speed Spindles and Production Line Equipment

High-speed spindles and precision production equipment demand emergency response when vibration threatens product quality or equipment integrity. Machine tool spindles affecting part accuracy, grinding equipment producing finish defects, and high-speed processing machinery all benefit from our emergency capabilities. We achieve precision balance quality meeting demanding tolerances even under emergency conditions. Our expertise with high-speed applications ensures proper correction without compromising the accuracy these critical components require.

Industries Across Metro Detroit Relying on Our Emergency Services

Dynamic Balancing Technologies provides emergency field balancing services to diverse industries throughout Metro Detroit, Macomb County, Wayne County, and Oakland County. Automotive manufacturing plants and their extensive supplier networks depend on our rapid response when production equipment failures threaten delivery schedules. Steel processing facilities trust our capabilities with heavy industrial equipment operating under demanding conditions. Power generation stations rely on our emergency services for turbines and critical rotating machinery affecting regional electrical supply.

Our emergency response capabilities also serve aerospace manufacturing operations where equipment failures impact flight-critical component production. Paper mills utilize our rapid response for continuous process equipment where downtime accumulates substantial losses hourly. Food processing facilities call on our emergency team when production schedules face disruption from rotating equipment problems. Chemical plants, pharmaceutical manufacturers, and healthcare institutions all benefit from our 24-hour availability ensuring critical equipment receives immediate professional attention whenever failures occur.

What to Expect During an Emergency On-Site Balancing Call

When you contact us for emergency field balancing service, our team immediately begins coordinating response logistics. We confirm your location, equipment details, and access arrangements while dispatching the nearest qualified technician. Our coordinator provides estimated arrival time and maintains communication throughout mobilization. We ask about safety requirements, personal protective equipment needs, and any facility-specific procedures our technician must follow upon arrival.

Our technician arrives with complete equipment for diagnosing and correcting your vibration problem. We begin with rapid assessment confirming the situation and identifying the most efficient restoration approach. Throughout the service, we communicate progress and any findings requiring your attention. Following successful balancing, we provide documentation of measurements and corrections performed. Our technician ensures your operations team understands equipment status before departing, confirming successful restoration and answering any questions about the work completed.

Why Choose Dynamic Balancing Technologies for Emergency Response

Selecting the right emergency field balancing partner ensures critical equipment receives expert attention when failures occur. Our capabilities and commitment distinguish our emergency services throughout Michigan.

Experienced Technicians Available Around the Clock

Our technicians bring over 33 years of combined industry experience to every emergency call. This extensive background enables rapid problem diagnosis and efficient correction under pressure. We have successfully balanced equipment across diverse applications from precision spindles to massive industrial fans. Around-the-clock availability means experienced professionals respond regardless of when your emergency occurs, providing expert attention during nights, weekends, and holidays.

Advanced Portable Diagnostic Equipment

Our emergency response vehicles carry state-of-the-art portable vibration analysis and balancing equipment. This advanced instrumentation provides accurate measurements and precise correction calculations comparable to permanent laboratory installations. We maintain equipment calibration and readiness ensuring reliable performance during emergency deployments. Complete tool and material inventories enable handling most situations without delays for additional supplies, accelerating your equipment restoration.

Proven Track Record with Detroit Area Manufacturers

Dynamic Balancing Technologies has built strong relationships with manufacturers throughout Southeast Michigan through consistent delivery of exceptional emergency response. Our customers trust our rapid response capabilities based on proven performance during their critical situations. We understand Detroit manufacturing requirements and the urgency production environments demand. This regional expertise combined with our commitment to customer service has established our reputation as the trusted emergency balancing partner.

Preventing Future Emergencies with Predictive Maintenance Programs

While emergency response capabilities remain essential, preventing failures before they occur delivers superior value for manufacturing operations. Our predictive maintenance programs establish baseline vibration measurements for critical rotating equipment, then monitor trends over time identifying developing problems. This proactive approach detects emerging imbalance conditions before they reach emergency levels, allowing planned interventions at convenient times rather than disruptive emergency responses.

Dynamic Balancing Technologies offers comprehensive monitoring programs with quarterly, biannual, or annual intervals tailored to your equipment criticality and operating conditions. Regular professional assessment identifies optimal timing for preventive balancing services. Equipment maintained through predictive programs consistently achieves extended service life while virtually eliminating unexpected failures requiring emergency response. Our monitoring customers throughout Detroit experience dramatically reduced emergency incidents while maintaining superior equipment reliability supporting consistent production performance.

Frequently Asked Questions About Emergency Field Balancing Services

How Quickly Can You Respond to an Emergency Balancing Call in Detroit?

Our response time depends on technician location and current commitments when your call arrives. We prioritize true emergencies and typically reach Detroit area facilities within hours of initial contact. Remote locations may require additional travel time. We communicate realistic arrival estimates immediately upon receiving your call.

What Information Should I Have Ready When Calling for Emergency Service?

Prepare equipment identification including type, size, and operating speed if known. Note symptoms observed including vibration severity, unusual sounds, and when problems began. Have facility address and contact information ready. Access requirements, safety procedures, and any time constraints help us prepare appropriately for efficient service upon arrival.

Do You Provide Emergency Balancing Services Outside Normal Business Hours?

Yes, Dynamic Balancing Technologies provides 24-hour emergency on-site balancing services throughout Metro Detroit and beyond. Our technicians respond to urgent calls during nights, weekends, and holidays when critical equipment failures cannot wait for regular business hours. We understand manufacturing emergencies occur anytime and maintain readiness accordingly.

What Is the Typical Duration of an Emergency Field Balancing Service?

Most single-rotor emergency balancing jobs complete within two to four hours including setup, diagnosis, correction, and verification. Complex multi-plane balancing or equipment requiring extensive access preparation may require additional time. We provide duration estimates after initial assessment and communicate progress throughout the service.

Can You Balance Equipment That Has Never Been Balanced Before?

Yes, we regularly balance equipment that has never received professional balancing attention. Our diagnostic process identifies current imbalance conditions regardless of equipment history. We establish appropriate balance quality targets based on equipment type and operating requirements, then achieve corrections meeting those specifications through our standard precision procedures.

Get Immediate Help for Your Detroit Manufacturing Emergency

When critical rotating equipment fails and production cannot wait, Dynamic Balancing Technologies provides the emergency field balancing response Detroit manufacturers depend upon. Our experienced technicians, advanced portable equipment, and commitment to rapid response ensure your urgent situations receive immediate professional attention. Contact our emergency line when equipment failures threaten your operations and let our team restore your rotating machinery quickly, minimizing downtime and protecting your production schedules.