At Dynamic Balancing Technologies, we understand the critical role that rotating machinery plays in your daily operations. Whether you’re operating an HVAC system, manufacturing facility, or managing industrial equipment in Grand Rapids, Michigan, the health and stability of your machines are essential for productivity and safety. That’s why we’ve built our reputation on delivering high-quality, cost-effective dynamic balancing services tailored to the diverse needs of businesses across the region. Our focus on precision, responsiveness, and long-term reliability ensures that your machines perform efficiently with minimal downtime or unexpected failures. In this guide, we’ll share everything you need to know about finding and benefiting from professional dynamic balancing in Grand Rapids, MI.

What Is Dynamic Balancing and Why Your Grand Rapids Business Needs It

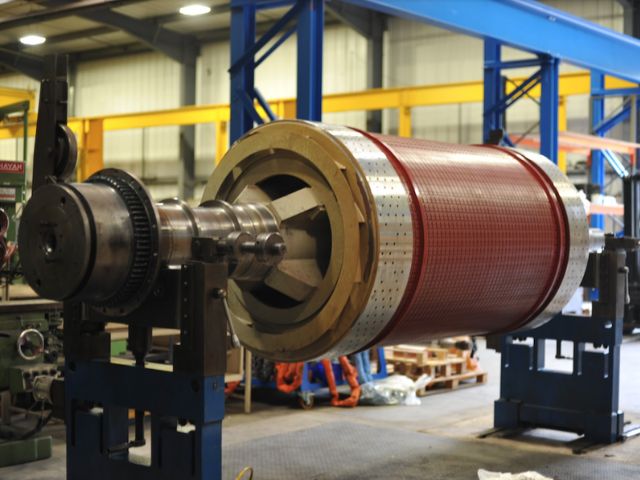

Dynamic balancing is the process of correcting the uneven mass distribution in rotating components such as rotors, shafts, fans, blowers, and spindles. When machinery is out of balance, it causes excessive vibration that leads to accelerated wear, inefficient performance, and even structural damage. At Dynamic Balancing Technologies, we offer advanced balancing solutions that identify and resolve these issues using state-of-the-art technology and proven methodologies.

Businesses across Grand Rapids rely heavily on rotating equipment, particularly in industries such as automotive, aerospace, food processing, HVAC, medical, and energy. With dynamic balancing, we help our clients reduce vibration-related failures, extend the lifespan of their equipment, and improve overall operational efficiency. Our services are particularly crucial for manufacturers, hospitals, and large-scale industrial facilities where uninterrupted operation is essential. By investing in professional balancing and diagnostics, your business can significantly reduce repair costs while enhancing performance and safety.

Understanding the Signs You Need Rotating Equipment Balancing

Recognizing the early warning signs of imbalance can save your business from costly repairs and unplanned downtime. We often receive calls from companies that notice unusual machine vibrations, louder-than-normal operation, or sudden wear on bearings and seals. These symptoms typically indicate unbalanced components that are straining your system.

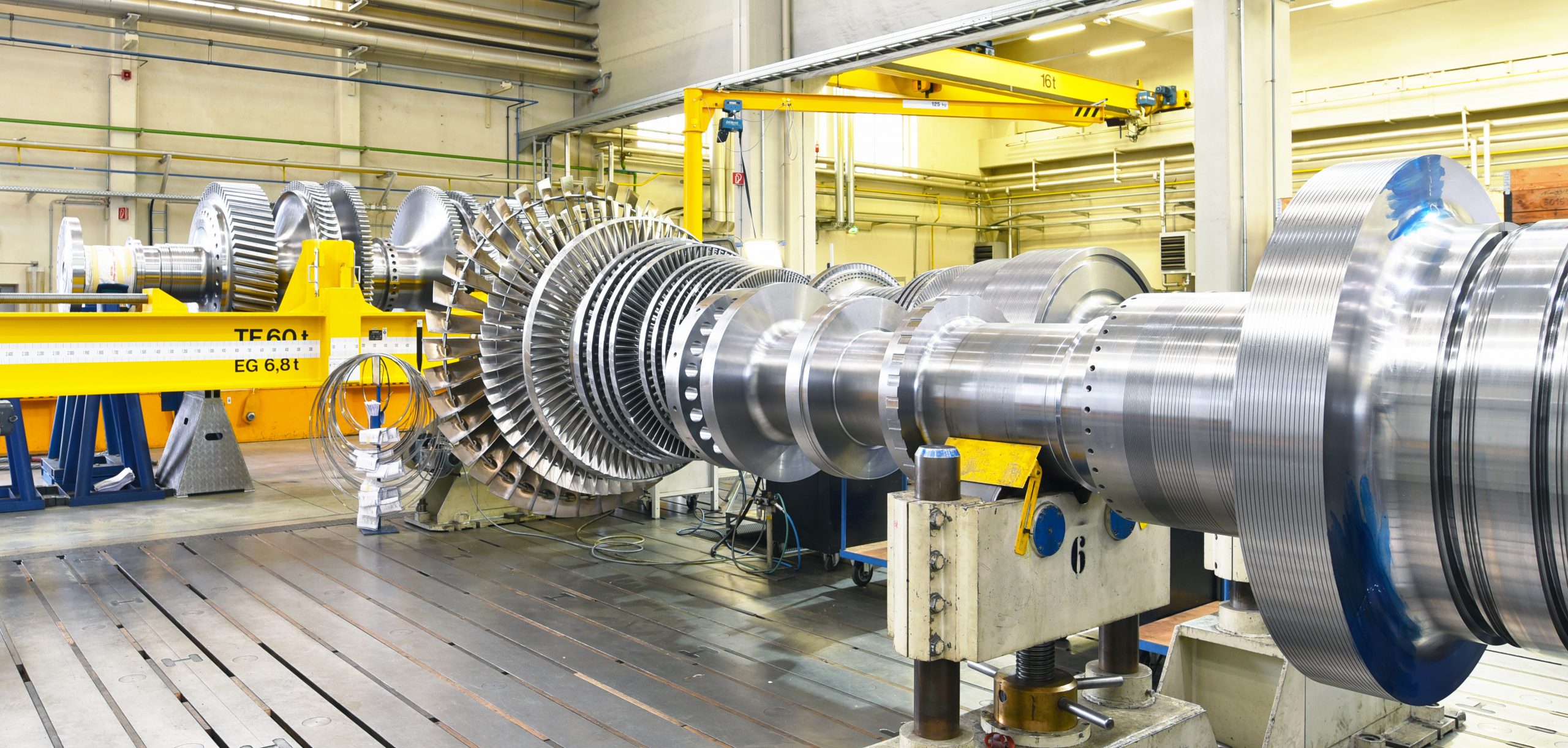

In Grand Rapids, equipment that’s exposed to frequent startup and shutdown cycles—such as industrial fans, compressors, electric motors, and turbines—is especially prone to imbalance over time. As misalignment grows, so does the risk of machine failure. Excessive heat generation, resonance, and reduced energy efficiency are all common consequences of ignoring balancing issues.

At Dynamic Balancing Technologies, we combine decades of experience with advanced tools to diagnose and correct imbalance before it becomes a significant problem. Our dynamic balancing services are ideal for clients who want to avoid costly rebuilds and instead invest in preventive maintenance that delivers measurable results.

Core Services Offered by Dynamic Balancing Technologies in Grand Rapids, MI

As a nationwide provider of industrial maintenance services, we’re proud to offer a full suite of dynamic balancing services to businesses in Grand Rapids and surrounding communities. Each of our services is designed to enhance equipment performance, minimize operational stress, and help clients maintain safe, compliant, and cost-effective operations.

Our dynamic and static balancing services address a wide range of rotating components. Whether you’re dealing with rotors, electric motors, tooling, or fans, we use in-shop and on-site methods to restore balance and eliminate vibration. For parts up to 250 pounds, our static balancing process ensures stability in components that operate at lower speeds or in fixed positions. For high-speed or heavy-duty equipment, dynamic balancing provides more precise correction, especially for shafts and rotating assemblies.

We also offer field balancing services, which are especially popular among industrial clients in Grand Rapids who can’t afford the downtime involved with removing equipment. Our technicians bring advanced portable equipment directly to your site, perform balancing with minimal disruption, and deliver instant results. On-site dynamic balancing reduces maintenance costs, prevents production delays, and ensures that your systems remain in peak operating condition.

Our vibration analysis services are designed to complement balancing and provide a complete picture of your equipment’s health. Using advanced vibration sensors and analysis software, we identify imbalances, misalignments, bearing wear, and structural resonance. This service is ideal for facilities that rely on predictive maintenance to anticipate failures before they occur. We deliver detailed reports that pinpoint the root causes of vibration and recommend corrective actions, saving you time and money.

Our predictive maintenance programs go a step further by offering scheduled vibration monitoring for critical equipment. With ongoing monitoring, we track changes in machine behavior over time, allowing you to make informed decisions about maintenance and replacements. This proactive approach ensures long-term reliability and lowers the total cost of ownership for your machinery.

We also specialize in laser shaft alignment, which is crucial for reducing mechanical stress on couplings and extending the life of bearings. Misaligned shafts are a common source of vibration and energy loss. Our precision alignment services ensure that your equipment is perfectly aligned to manufacturer specifications, maximizing efficiency and reducing the risk of failure.

Industries We Serve in the Grand Rapids Area

Our experience spans a wide range of industries, and we’ve tailored our services to meet the specific needs of each. In Grand Rapids, we commonly support automotive and aerospace manufacturers, both of which require highly precise balancing for motors, spindles, and custom tooling. Our field balancing and vibration diagnostics help these companies maintain quality control and avoid costly production issues.

We also serve medical institutions and hospital systems that rely on uninterrupted HVAC systems, surgical equipment, and clean room ventilation. Vibration and imbalance in these environments can compromise patient safety and disrupt critical care services. That’s why facility managers and maintenance engineers throughout the region trust our services.

The power generation industry benefits significantly from our expertise in dynamic balancing and vibration analysis. Whether you operate turbines, backup generators, or distribution systems, we ensure your equipment operates at optimal performance to minimize energy loss and prevent system degradation.

Food processing plants, paper mills, and packaging facilities also turn to us for reliable balancing and predictive maintenance. These industries often operate machinery 24/7, making preventive services essential for maintaining continuous output and ensuring safety compliance. By partnering with Dynamic Balancing Technologies, these businesses gain peace of mind knowing their equipment is protected by seasoned professionals who understand their operational demands.

Tips to Find Affordable Dynamic Balancing Services in Grand Rapids, MI

Finding the right dynamic balancing provider in Grand Rapids can be a challenge if you’re unfamiliar with what to look for. Many providers offer balancing as part of a broader mechanical repair service, but few specialize in it with the level of precision, responsiveness, and customization that we do.

We recommend choosing a provider who offers both in-shop and on-site balancing. This flexibility can drastically reduce the time and cost associated with transporting heavy or sensitive equipment. It’s also important to ask about the tools and techniques being used. At Dynamic Balancing Technologies, we rely on ISO-certified procedures, precision vibration analysis software, and high-quality balancing machines that meet strict industry standards.

Look for a company that provides complete documentation and diagnostic reports. Transparent reporting is a sign of professional integrity and helps you understand the value of the service you’re receiving. Our team provides detailed balancing logs, vibration spectra, and equipment history, allowing you to track improvements over time.

Affordability isn’t just about the cheapest price. It’s about choosing a company that can help you prevent future breakdowns, minimize emergency repair costs, and extend equipment lifespan. We offer customizable service packages that match your budget and operating schedule while delivering measurable ROI through reduced downtime and energy usage.

How Dynamic Balancing Technologies Ensures Cost-Efficiency and Reliability

Our commitment to cost-effective service is backed by over three decades of combined experience in dynamic balancing, vibration diagnostics, and mechanical alignment. We take pride in being responsive, technically accurate, and customer-focused in every engagement.

From the moment you contact us, we prioritize open and transparent communication. We’ll discuss your machinery, operating conditions, past maintenance history, and performance concerns. Our team then proposes a tailored solution that includes a clear scope of work, timeline, and pricing estimate. Whether we’re performing dynamic balancing on a 1000 RPM fan or a high-speed spindle, our methods are precise and repeatable.

We use state-of-the-art balancing machines for in-shop service and portable balancers with laser sensors for field balancing. Our vibration analysis reports are easy to understand and include insights that help you make smart maintenance decisions. Clients appreciate the fact that we not only solve their immediate problem but also offer recommendations for long-term reliability.

With our emergency response team available 24/7, we’re ready to support urgent needs across Grand Rapids and beyond. If a production line is down or a motor is vibrating excessively, we’ll be there with the tools and expertise to restore balance—fast.

FAQ – Dynamic Balancing in Grand Rapids, MI

What’s the difference between static and dynamic balancing?

Static balancing addresses imbalances in a stationary position, often used for components that rotate slowly. Dynamic balancing, on the other hand, measures and corrects imbalance while the component is in motion, making it more effective for high-speed equipment and rotating assemblies.

How much does dynamic balancing cost in Grand Rapids?

Pricing varies depending on equipment size, location, and complexity. We offer competitive rates and customized service packages that ensure cost-effectiveness while maintaining high standards of precision and safety.

Can you perform balancing on-site?

Yes. Our mobile field technicians travel throughout Grand Rapids and the surrounding areas to perform on-site balancing, vibration analysis, and shaft alignment. This minimizes downtime and eliminates the need to transport heavy machinery.

What types of machines can be balanced?

We balance a wide variety of equipment, including rotors, fans, electric motors, spindles, pumps, turbines, blowers, and more. Our services are applicable to nearly all rotating machinery across various sectors, including manufacturing, HVAC, energy, and healthcare.

Do I need vibration analysis before balancing?

While not always required, vibration analysis helps identify the root cause of imbalance or misalignment. We often recommend it as part of a comprehensive diagnostic approach, especially for clients who want to manage their equipment’s health proactively.

Contact Dynamic Balancing Technologies in Grand Rapids, MI Today

If your business relies on rotating machinery and you want to ensure safe, efficient, and long-lasting operation, we invite you to connect with our team. At Dynamic Balancing Technologies, we offer on-site balancing, predictive maintenance, and vibration diagnostics throughout Grand Rapids and the greater Michigan region.

We welcome inquiries from manufacturing plants, hospitals, facility managers, and maintenance teams looking for reliable and affordable balancing solutions. Whether you’re interested in a one-time service or a comprehensive maintenance contract, we’re here to help. Contact us today to discover how our dynamic balancing and vibration analysis services can safeguard your equipment, enhance performance, and lower operating costs. With flexible scheduling, transparent reporting, and expert technicians, we’re the trusted partner your machines deserve.