Industrial Field Balancing in Westland, MI – Dynamic Balancing Technologies

Expert On-Site Industrial Field Balancing Services in Westland, Michigan

Dynamic Balancing Technologies provides expert industrial field balancing in Westland, MI, designed to eliminate vibration, extend equipment life, and improve the overall performance of rotating machinery. With over 33 years of industry-leading experience, we serve businesses throughout the Westland area with fast, reliable, and accurate on-site balancing solutions. Our technicians are equipped with advanced portable tools to correct the imbalance without removing the equipment, minimizing downtime and maximizing precision. We perform on-site dynamic balancing in Westland for a wide variety of rotating components, including fans, blowers, spindles, and drive shafts. Our services are ideal for manufacturing facilities, automotive suppliers, steel processors, and energy producers operating in and around the Westland area. Whether you're facing vibration issues or want to prevent them before they start, we provide comprehensive industrial equipment balancing in Westland, MI, to keep your operations running smoothly and efficiently.

What Is Industrial Field Balancing and Why It Matters

Industrial field balancing is the process of correcting an imbalance in a rotating component while it is installed and in operation under real-world conditions. Unlike static balancing, which is performed off-site on stationary equipment, dynamic field balancing enables us to identify and correct imbalances in the environment where the equipment operates daily. This leads to more accurate and long-lasting results. Static balancing is suitable for slow-speed or small equipment. However, it does not account for variables such as load changes, shaft misalignment, thermal expansion, or mounting conditions. Dynamic balancing, performed while the rotor spins, addresses these variables in real-time. This approach reduces machine stress, prevents early bearing failure, and improves operational reliability. At Dynamic Balancing Technologies, we utilize sophisticated tools, including FFT analyzers and proximity sensors, to diagnose rotor imbalance, calculate phase angles, and apply corrective weights. Our goal is to eliminate destructive vibration and optimize machine reliability. Familiar entities addressed during our service include rotor imbalance, vibration analysis, critical speed, and machine structural resonance.

Our Westland Field Balancing Expertise

Dynamic Balancing Technologies has proudly served Michigan’s industrial sector for over three decades. Our experienced technicians in Westland bring a deep understanding of rotating machinery and deliver customized balancing solutions for clients of all sizes. From one-off emergency service calls to long-term predictive maintenance programs, we’re the trusted partner for all your vibration correction needs. We frequently support operations in Westland’s manufacturing plants, steel processing facilities, and automotive supply chains. Our field balancing for automotive machinery in Westland is especially critical in high-precision environments, where even slight imbalances can significantly impact production quality. Whether you’re dealing with high-speed production spindles, motor-driven assemblies, or HVAC blowers, we ensure your equipment is balanced to ISO standards. Our team not only fixes problems but also helps clients understand the root causes of imbalances, enabling them to improve their maintenance practices and system performance.

What Types of Equipment We Balance On-Site

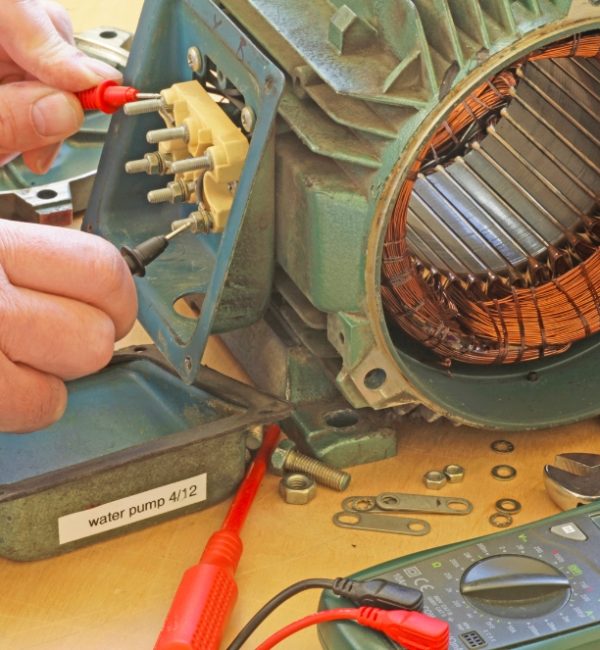

We offer on-site balancing for a wide range of rotating equipment commonly found in industrial settings. Using portable equipment, we analyze and correct imbalances in the following components:

Fans, blowers, spindles, shredders, drive shafts, HVAC systems, and electric motors.

Imbalance in these systems can lead to excessive vibration, structural fatigue, noisy operation, reduced productivity, and premature component wear. Our rotating equipment balancing services allow us to correct single-plane and two-plane unbalance with precision, helping your machines run quieter and longer.

We’re specialists in field rotor balancing in Westland and adapt our services to meet your specific equipment configuration, speed range, and accessibility constraints.

How the Industrial Field Balancing Process Works

Our process follows four precise steps to ensure your equipment is accurately and efficiently balanced:

First, we perform an initial vibration analysis using FFT analyzers, tachometers, and accelerometers to detect the level and source of imbalance. This phase allows us to collect baseline data and identify operational conditions that affect the rotor.

Second, we diagnose the imbalance by calculating the vibration’s phase angle and magnitude. From there, we determine the optimal placement and amount of balancing weight required to restore stability.

Third, we execute the balance correction by installing counterweights on the rotor while it’s operating. This enables real-time monitoring of changes, ensuring that each adjustment produces the desired results.

Fourth, we conduct a post-balancing vibration test and deliver a comprehensive report detailing the issue, the steps taken to correct it, the final vibration levels, and ongoing maintenance recommendations.

Highly related terms and tools used in our process include FFT analyzer, phase angle detection, balancing weights, field balancer, and predictive maintenance tracking.

Why Choose Dynamic Balancing Technologies in Westland, MI

There are many reasons why businesses throughout Westland choose Dynamic Balancing Technologies for industrial field balancing. Our team is local, responsive, and highly experienced in dealing with the region’s industrial equipment challenges. We offer 24/7 emergency service for vibration-related issues that can’t wait, as well as flexible scheduling for preventive balancing programs.

Our status as trusted Westland industrial balancing experts comes from our commitment to precision, safety, and reliability. We approach every project with a solution-focused mindset, aiming to provide more than just a fix—we help clients develop innovative maintenance strategies and reduce long-term repair costs. We are fully equipped to handle high-volume facilities, sensitive machinery, and tight production timelines without sacrificing accuracy.

Serving Westland and Surrounding Michigan Cities

Dynamic Balancing Technologies proudly serves Westland and neighboring industrial areas with mobile on-site balancing services. Our coverage includes but is not limited to Dearborn, Livonia, Sterling Heights, Flint, and Ann Arbor. Whether you operate a local machine shop or a central manufacturing plant, we bring our expertise directly to your location.

Our ability to deliver on-site rotor balancing near Westland, MI, means less downtime, lower costs, and greater control over your production schedule. No need to ship equipment off-site or halt production for days—our technicians arrive, diagnose, correct, and verify, often in a single visit.

Frequently Asked Questions (FAQs)

What causes an imbalance in rotating machinery?

Imbalance is typically caused by uneven mass distribution, dirt buildup, worn components, or improper assembly. It often results in vibration, noise, and decreased efficiency.

How long does field balancing take?

Most field balancing jobs can be completed within 2–4 hours, depending on equipment size and complexity. Emergency jobs may be resolved even faster.

Is it safe to balance equipment while it's operating?

Yes. Our technicians are trained to safely balance machinery during regular operation, allowing us to capture accurate real-time data and deliver precise results.

Can I schedule balancing during a maintenance shutdown?

Absolutely. We frequently coordinate with maintenance teams during planned outages to ensure minimal disruption and maximum value.

Does the service include documentation?

Yes. We provide detailed reports that include vibration readings, corrections performed, balance quality grades, and recommendations for ongoing maintenance.

Contact Us for Industrial Field Balancing in Westland, MI

If your equipment is vibrating, producing unusual noise, or suffering from early bearing wear, contact Dynamic Balancing Technologies for professional industrial field balancing in Westland, MI. We’ll eliminate imbalance, reduce mechanical stress, and help you get more life out of your equipment.

Phone: (586) 280-8256

Email: dynamicbalancingtech@gmail.com

Schedule your on-site balancing service today. Speak with a Westland-based vibration analysis expert and get your operation running smoother than ever.