We at Dynamic Balancing Technologies know that consistent machinery performance is critical for Detroit’s manufacturing plants, industrial facilities, and production operations. Modern production requirements have intensified the rotating equipment maintenance Detroit operational demands on Detroit’s motors, pumps, spindles, blowers, and rotating equipment. Manufacturing facilities face compressed production timelines, escalating energy expenses, and the critical need for uninterrupted operations. Predictive Maintenance Service in Detroit, MI gives facilities a strategic advantage by ensuring equipment is monitored through real-time data, vibration signatures, and condition-based metrics that reveal early signs of failure long before they can damage productivity or shorten machine life. Our methodology centers on maximizing machinery longevity, decreasing operational burden, and establishing enduring dependability across Detroit’s manufacturing sector. Our team employs sophisticated vibration diagnostics, precision balancing, laser alignment technology, and continuous monitoring systems to shield machinery from concealed stresses that slowly compromise component integrity. Our emphasis on data-driven predictions instead of emergency responses enables Detroit facilities to attain superior performance, enhanced efficiency, and prolonged machinery service life.

Understanding Predictive Maintenance Service in Detroit, MI for Industrial Equipment Health

For Detroit manufacturers, predictive maintenance represents a revolutionary approach to equipment care that eliminates disruptive downtime. Instead of relying on time-based intervals, predictive maintenance measures the actual health of machinery and uses that information to determine the right time for service. In a city known for energy facilities, steel manufacturing, automotive production, and aerospace machining, equipment health directly influences daily operations and long-term planning. This advanced approach eliminates uncertainty through comprehensive analysis of vibration signatures, thermal variations, load inconsistencies, performance degradation, and additional factors affecting rotating equipment longevity. Consequently, Detroit operations achieve greater scheduling flexibility, prevent premature component deterioration, and foster safer, more productive manufacturing settings.

Critical Monitoring Parameters That Safeguard Industrial Equipment

This maintenance approach emphasizes continuous observation of genuine machine behavior rather than responding to advanced deterioration. Through vibration measurement we discover balance and alignment problems, thermal scanning identifies heat-related concerns and friction issues, while condition assessment exposes unseen deterioration in critical components like bearings and shafts. These indicators matter because Detroit’s industrial operations rely heavily on machinery that operates at high speeds, under heavy load, and for long durations. Vigilant observation of these elements enables us to address developing concerns quickly, stopping cumulative wear and optimizing equipment lifespan.

Dynamic Balancing Technologies’ Approach to Extending Machinery Service Life

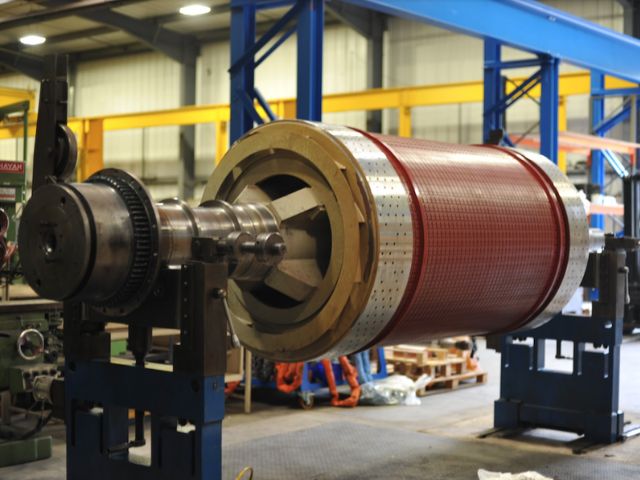

Our team specializes in services that directly support equipment health and long-term reliability. Our cutting-edge vibration assessment capabilities reveal slight alterations that warn of equipment stress far in advance of system failures. Our balancing procedures return rotational stability to equipment by removing imbalance conditions that cause harmful vibrations and mechanical deterioration. Laser-guided alignment technology guarantees exact positioning of coupled elements, minimizing friction and averting accelerated degradation of internal components. Field-based diagnostic capabilities enable Detroit facilities to obtain instant evaluations while keeping equipment in active operation. Regardless of whether machinery includes electric motors, ventilation systems, pumps, compression equipment, or precision spindles, our maintenance strategies extend component lifecycles while enhancing overall performance.

Benefits of Predictive Maintenance Services for Detroit Manufacturing Plants

Predictive maintenance increases equipment longevity by preventing destructive operating conditions from developing unnoticed. Detroit operations gain advantages including decreased emergency stoppages, minimized repair expenditures, and strengthened production reliability. When machinery operates within optimal parameters, energy usage decreases, noise levels drop, and stress on internal components weakens significantly. This approach guarantees more effective budget allocation since maintenance activities occur only when actual diagnostic information confirms the need. Facilities implementing predictive programs create more secure workplaces by preventing failure scenarios that cause fires, seized bearings, mechanical collisions, and safety risks.

Detroit Sectors Depending on Predictive Maintenance Solutions

Multiple Detroit-based industries depend heavily on Predictive Maintenance Service in Detroit, MI because the city’s industrial identity revolves around continuous operation. Automotive manufacturing facilities depend on predictive strategies to safeguard conveyor systems, motor assemblies, ventilation equipment, and precision machinery from accelerated deterioration. Aviation industry producers employ predictive analysis to protect precision spindle assemblies, rotational equipment, and sophisticated machining elements. Power generation plants depend on predictive analysis to maintain turbines, compressors, and generators. Steel mills, food processing plants, and chemical facilities profit from predictive strategies because their environments subject rotating equipment to severe operational conditions. Predictive methodologies benefit any sector employing demanding equipment by increasing service longevity and strengthening performance consistency.

Predictive Maintenance Techniques Used by Dynamic Balancing Technologies

Dynamic Balancing Technologies employs Dynamic Balancing Technologies Detroit multiple sophisticated diagnostic techniques to assist Detroit companies in prolonging equipment service life. Vibration signature tracking enables us to observe progressive changes that reveal emerging Dynamic Balancing Technologies mechanical instability. Precision balancing services rectify imbalanced rotational elements that impose excessive loads on mechanical internals. Laser alignment ensures precision alignment of shafts to prevent heat build-up and material fatigue. Field-based condition assessment delivers ongoing insight into equipment operational status. Our corrective approaches depend solely on measured data rather than speculation, confirming that each maintenance choice promotes sustained machinery longevity.

What Makes Dynamic Balancing Technologies Detroit’s Preferred Maintenance Partner

We possess greater than three decades of unified experience in mechanical health monitoring, reliability analysis, and manufacturing diagnostics. Detroit companies rely on us because we use advanced tools and proven methods to provide accurate, actionable insights into machine performance. We provide internationally-standardized balancing, high-precision alignment, and specialist diagnostic evaluation to maintain equipment within perfect operational ranges. Rapid response capabilities throughout Detroit and Southeast Michigan enable facilities to resolve critical reliability issues promptly. Each maintenance strategy we develop is completely tailored to address the specific operational requirements and machinery configurations of individual facilities. This tailored approach helps Detroit companies maintain higher productivity, reduce downtime, and support equipment longevity at every operational stage.

How Predictive Maintenance Outperforms Traditional Approaches

Predictive strategies contrast sharply with preventive programs and breakdown maintenance because they react to genuine equipment status rather than arbitrary timelines or total system collapse. Predictive maintenance reduces unnecessary maintenance tasks that drive up costs and interrupt production. This strategy also averts the devastating equipment failures characteristic of reactive maintenance models. Detroit manufacturers recognize that predictive strategies deliver sustained economic benefits through prolonged machinery service life, enhanced equipment dependability, and failure prevention before operational disruption occurs. The difference in cost outcomes becomes especially clear when facilities track how much they save by eliminating emergency repairs, replacing fewer components, and maintaining tighter control over production schedules.

Additional Industrial Services Supporting Predictive Maintenance in Detroit

Various complementary solutions enhance predictive maintenance by improving performance throughout complete machinery systems. Electric motor diagnostics verify that motor systems function within optimal electrical load parameters and thermal conditions. Precision balancing of fans and blowers safeguards the mechanical integrity of air-moving equipment prevalent in Detroit manufacturing plants. Precision spindle services uphold machining exactness and manufacturing precision across production operations. Preventive maintenance add-ons allow Detroit facilities to combine predictive data with scheduled protection tasks, giving machinery long-term support and reducing stress on components.

Financial Benefits of Predictive Maintenance for Detroit Manufacturers

This maintenance approach enhances ROI through substantial decreases in repair expenditures, prolonged machinery service duration, and elimination of production disruptions. Data-driven maintenance choices enable Detroit facilities to eliminate inefficient expenditures and direct resources toward areas yielding maximum value. Predictive approaches ensure machinery maintains consistent performance over prolonged durations, minimizing the risk of abrupt system failures. This operational consistency enhances manufacturing throughput, generates superior quality results, and preserves sustained asset worth throughout Detroit’s production landscape.

Service Areas for Dynamic Balancing Technologies in Southeast Michigan

We deliver predictive maintenance solutions throughout Detroit, MI and neighboring communities such as Sterling Heights, Warren, Troy, Dearborn, Auburn Hills, Ann Arbor, and additional Southeast Michigan manufacturing centers. Detroit’s thriving manufacturing environment relies on machinery maintaining dependable operation across prolonged cycles, and our comprehensive geographic reach ensures every plant obtains the support essential for guarding against unanticipated deterioration and diminished equipment longevity. Our mobile service capabilities deliver solutions directly to manufacturing facilities, rendering predictive maintenance convenient, effective, and adaptable to local operational requirements.

Beginning Your Predictive Maintenance Journey with Dynamic Balancing Technologies

Beginning a predictive maintenance program starts with a comprehensive baseline assessment. This provides insight into the current condition of your machinery using vibration signatures, alignment data, performance metrics, and operational analysis. After completing the baseline analysis, we construct a personalized predictive program designed for your operation’s unique demands. The program incorporates diagnostic capabilities, continuous monitoring systems, and regular reporting mechanisms to guarantee Detroit manufacturers maintain awareness of machinery condition. Continuous monitoring ensures that equipment longevity improves progressively with every maintenance cycle. We strive to help Detroit manufacturers preserve their essential assets by confirming each piece of equipment runs safely, effectively, and achieves maximum operational longevity.

Detroit Predictive Maintenance FAQs

Why is predictive maintenance superior to scheduled preventive maintenance?

Predictive maintenance measures real-time machine health using vibration analysis, thermal monitoring, and mechanical data. This methodology guarantees service occurs exclusively when data indicates necessity, thereby prolonging machinery service life throughout Detroit manufacturing operations.

What types of Detroit businesses gain the greatest advantages from predictive maintenance?

Predictive maintenance benefits automotive production lines, aerospace manufacturers, steel plants, chemical processors, power generation facilities, and any Detroit industry that operates heavy rotating equipment requiring long-term reliability.

What role does predictive maintenance play in avoiding unplanned production stoppages?

Predictive diagnostics identify early warning signs such as imbalance, misalignment, or bearing fatigue. By correcting these issues early, Detroit businesses can avoid equipment shutdowns and maintain consistent production output.

How does predictive maintenance impact repair budgets and component replacement costs?

This maintenance approach decreases extended-term repair costs by preventing breakdowns necessitating significant parts replacement. Early detection ensures that equipment repairs remain minor and affordable.

How soon can Detroit facilities begin benefiting from predictive maintenance?

Most Detroit facilities can begin their predictive maintenance program shortly after the baseline assessment. Information collection, analytical procedures, and surveillance capabilities implement swiftly, permitting businesses to realize extended machinery life expectancy without delay.

Enhancing Industrial Reliability Across Detroit’s Manufacturing Sector

We improve operational consistency across Detroit’s industrial landscape by merging cutting-edge diagnostics, expert personnel, and personalized monitoring technologies. Detroit manufacturers are welcome to contact Dynamic Balancing Technologies anytime they require assistance maximizing machinery efficiency or prolonging essential equipment lifespan. We stay dedicated to delivering precise diagnostic intelligence, rapid service deployment, and enduring strategies for enhancing manufacturing equipment condition.