Detroit’s automotive and manufacturing plants thrive on reliable machinery and advanced production systems that require consistent performance. When equipment fails unexpectedly, it results in downtime, revenue loss, and expensive repairs. At Dynamic Balancing Technologies, we deliver proven vibration analysis services that safeguard Detroit’s automotive and manufacturing plants. Our services identify hidden equipment issues before they escalate into major breakdowns. Our approach keeps production continuous while avoiding emergency repairs. Our vibration analysis service becomes an integral part of each facility’s predictive maintenance program.

Why Vibration Analysis Matters for Detroit Industries

As part of predictive maintenance, vibration analysis is a core strategy for Detroit industries. Each machine generates unique vibrations that act as a signature of its operating condition. Variations in vibration signatures often highlight potential equipment failures. We rely on FFT analyzers and ISO-calibrated instruments to interpret vibration data. Brief production stoppages in automotive plants often lead to significant financial losses. With vibration analysis, Detroit facilities plan maintenance effectively and avoid disruptions.

Specialized Vibration Analysis Services for Detroit Facilities

We conduct vibration diagnostics that highlight performance and hidden equipment issues. We measure vibration in motors, compressors, pumps, turbines, and conveyors to uncover hidden faults. ISO-calibrated tools and FFT analyzers help us identify imbalance, looseness, and resonance. These diagnostics form the backbone of Detroit’s predictive maintenance programs. The insights from vibration analysis improve reliability and machine durability.

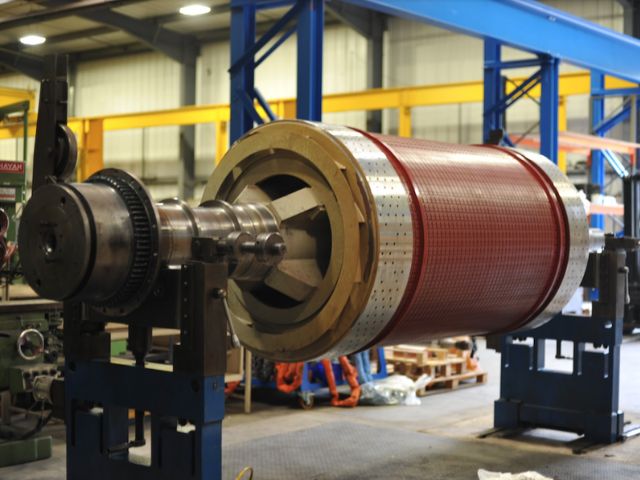

On-Site Industrial Field Balancing Services in Detroit

One of the most common causes of vibration in Detroit industries is imbalance. Dynamic Balancing Technologies delivers on-site industrial field balancing directly at Detroit facilities. Our field balancing guarantees rotating equipment performs with maximum stability. We apply static and dynamic balancing methods for precision. On-site service minimizes downtime and supports productivity.

Laser Alignment Services for Detroit Equipment

Misaligned machinery causes vibration, shortens bearing life, and wastes energy. Our laser alignment services in Detroit eliminate these issues with precision. By aligning https://dynamicbalancingtechnologies.com/ motors, compressors, and turbines, we enhance equipment performance. Laser alignment improves energy efficiency while increasing lifespan.

Specialized Motor Repair and Spindle Balancing for Automotive Plants

High-speed spindles require exact balancing to maintain quality in production. We balance high-speed spindles to reduce vibration and increase performance. Our motor balancing solutions optimize Detroit plant equipment efficiency. Balancing reduces vibration, extends lifespan, and enhances energy efficiency.

Ongoing Equipment Monitoring for Automotive and Manufacturing Plants

Detroit plants gain condition monitoring programs with vibration analysis as the core. We track vibration changes to predict when repairs are required. Predictive monitoring allows Detroit plants to avoid emergency stoppages. Proactive programs increase uptime and prevent breakdowns.

Why Detroit Plants Trust Dynamic Balancing Technologies

We bring decades of experience to Detroit’s automotive and manufacturing plants. Our reputation is built on expertise, reliability, and customer success. Our technicians are available 24/7 for emergency vibration diagnostics. Our team combines advanced diagnostic tools with extensive field experience.

Key Benefits of Professional Vibration Analysis in Detroit MI

Early fault detection avoids costly breakdowns. Reducing downtime and extending equipment life are core benefits. Efficiency increases as balanced equipment consumes less energy. Fewer failures mean safer work environments. By investing in vibration analysis, Detroit industries gain financial and operational advantages.

Service Areas Across Detroit and the Midwest

We provide vibration analysis in Detroit as well as throughout the Midwest. Detroit-area coverage includes Ann Arbor, Warren, Dearborn, and Sterling Heights. Clients in Indiana, Ohio, Kentucky, and Illinois also benefit from our services.

Schedule Vibration Analysis with Dynamic Balancing Technologies

Scheduling vibration services with us is easy and efficient. We begin with consultations to assess plant needs. Our technicians use advanced diagnostic tools to collect detailed data. We provide transparent reports showing machinery condition and next steps. Detroit industries trust our transparent process to keep machinery reliable.

Frequently Asked Questions About Vibration Testing in Detroit MI

Why do Detroit automotive facilities need vibration analysis?

It reveals hidden faults such as looseness, bearing issues, and imbalance. Early detection lengthens equipment lifespan and avoids failures.

Does vibration analysis stop breakdowns in Detroit plants?

Absolutely, vibration analysis uncovers failures before they cause downtime. Facilities schedule repairs before emergencies happen.

What makes Dynamic Balancing Technologies reliable for Detroit vibration analysis?

Our 32 years of service make us a proven provider. Our tools meet ISO calibration standards. Detroit industries rely on us for round-the-clock support.

Do you provide emergency vibration analysis services in Detroit?

We provide emergency vibration testing anytime, day or night. Our rapid response minimizes downtime and disruption.

How can Detroit facilities book vibration testing with Dynamic Balancing Technologies?

Detroit plants reach us directly for scheduling. Our team evaluates equipment and runs detailed tests. We deliver clear reports with recommendations.

Conclusion: Reliable Vibration Analysis for Detroit Automotive and Manufacturing Plants

For Detroit’s industries, uptime is critical and downtime is costly. Unexpected breakdowns are disruptive and expensive. Vibration services help secure efficiency and reliability. We offer vibration Discover more here testing, balancing, and alignment tailored to Detroit plants. By partnering with us, Detroit facilities gain reliable maintenance allies.