Vibration Analysis in Southfield, MI – Dynamic Balancing Technologies

In Southfield’s thriving industrial sector, operational reliability can be the deciding factor between meeting production targets and facing costly delays. At Dynamic Balancing Technologies, we specialize in delivering high-precision vibration analysis in Southfield, MI to keep your machinery performing at its peak. Our services are designed to identify hidden equipment issues before they escalate into unplanned downtime, allowing your facility to maintain continuous, efficient production.

Why Choose Dynamic Balancing Technologies for Vibration Analysis in Southfield

With more than 33 years of experience in condition monitoring and machinery diagnostics, our approach is built on a deep understanding of industrial equipment and its operational demands. We specialize in predictive maintenance, a proactive strategy that allows businesses to address mechanical issues before they cause production interruptions. Our expertise spans all types of rotating equipment, from industrial pumps and fans to precision gearboxes and electric motors. Every vibration analysis we perform follows strict ISO 10816 standards, ensuring measurement accuracy and actionable reporting. We proudly serve Southfield’s diverse range of industries, including automotive manufacturing facilities, aerospace engineering plants, steel production operations, and other high-output manufacturing environments. When you work with us, you’re choosing a partner that is committed to keeping your equipment in top condition and your production lines running without disruption.

What is Vibration Analysis and How It Works

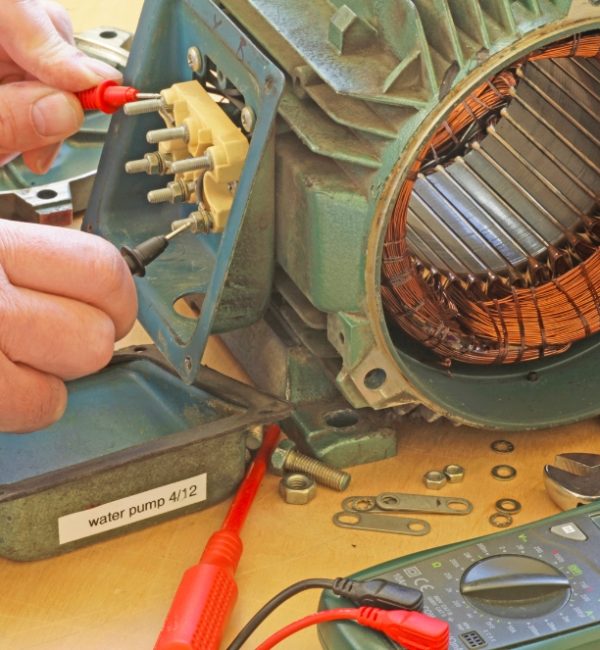

Vibration analysis is a specialized diagnostic process that evaluates the mechanical health of a machine by measuring and interpreting its vibration patterns. Every piece of machinery generates a unique vibration signature that reflects the condition of its internal components. Changes in that signature can be early indicators of mechanical faults. At Dynamic Balancing Technologies, we use high-sensitivity vibration sensors to gather precise data from key points on the equipment while it operates under normal conditions. The collected data is analyzed using Fast Fourier Transform (FFT) and modal analysis techniques, which break down complex vibration signals into identifiable components. This process allows us to detect imbalance, which can lead to uneven wear and premature component failure; misalignment, which causes increased friction and operational stress; bearing defects, which, if left unchecked, can cause severe damage; and gearbox issues, such as worn or damaged gears and lubrication problems. Beyond diagnosing faults, vibration analysis is critical for ongoing structural integrity assessments and equipment health monitoring, ensuring machinery operates safely and efficiently over time.

Benefits of Professional Vibration Analysis for Southfield Industries

For industrial businesses in Southfield, professional vibration analysis delivers benefits that directly impact efficiency, safety, and profitability. One of the most important advantages is early fault detection, allowing maintenance teams to repair or replace components before they cause unplanned shutdowns. This improves machinery reliability, enabling equipment to operate at optimal performance for longer periods and reducing the need for costly replacements. Enhanced reliability also means greater workplace safety, as the risk of unexpected equipment failures is minimized. With reduced unplanned downtime for rotating machinery, operations can maintain consistent output and meet production schedules without compromise. Adhering to maintenance engineering best practices and ISO vibration standards also strengthens your facility’s compliance credentials and instills greater confidence among clients and stakeholders.

Our Vibration Analysis Process

Our process is designed to deliver precise, actionable insights that guide effective maintenance decisions. It begins with an on-site consultation and equipment assessment, where we review your operational needs, production schedule, and machinery history. From there, we conduct data collection using advanced accelerometers and harmonic analysis tools to capture accurate vibration readings. Our team then performs a detailed frequency spectrum interpretation and historical trend analysis, comparing current data with baseline performance levels to identify any changes that indicate wear or malfunction. Based on the findings, we provide targeted recommendations, which may include dynamic balancing, laser alignment, bearing replacement, or gearbox servicing. Once corrective measures are implemented, we offer follow-up support through periodic condition monitoring and testing to ensure long-term equipment stability and performance.

Equipment & Technology We Use

The accuracy of our diagnostics comes from using industry-leading tools and technology. Our advanced vibration monitoring systems can detect even the smallest deviations from optimal performance. Portable dynamic balancing machines allow us to make precise adjustments on-site without dismantling machinery, reducing downtime and operational disruption. We also employ signal processing and resonance testing tools to uncover hidden faults that routine inspections may miss. Our real-time monitoring software integrates directly with predictive maintenance programs, enabling continuous oversight of equipment performance. To ensure reliability and precision in every analysis, we rely on trusted brands such as Brüel & Kjær, SKF, Fluke, Bentley Nevada, and Emerson AMS.

Industries We Serve in Southfield, MI

Southfield’s economy is powered by a range of industries that depend on reliable, high-performance machinery. In automotive manufacturing plants, our vibration analysis services help prevent line stoppages and maintain assembly efficiency. Steel mills and metal fabrication shops rely on us to keep heavy-duty equipment operating under high-load conditions. Aerospace engineering facilities trust our diagnostics to maintain the precision and safety of critical components. In textile production lines, we detect and correct imbalances in high-speed machinery, and for food processing plants, we help ensure consistent operation that meets strict hygiene and safety requirements. We also serve power generation and utility providers, where equipment reliability is crucial for uninterrupted service delivery.

Related Services from Dynamic Balancing Technologies

In addition to vibration analysis, we offer a range of complementary services to keep machinery running at its best. Our industrial field balancing services correct imbalances directly on-site, saving time and avoiding the need for disassembly. We provide both static and dynamic balancing for components of all sizes to ensure smooth operation. Our laser alignment services prevent misalignment-related wear and improve overall efficiency. We also perform electric motor repair and balancing, restoring optimal performance and extending service life. For a more proactive approach, our predictive maintenance programs integrate vibration analysis with other advanced diagnostics for comprehensive equipment management.

Service Areas Around Southfield, MI

While Southfield is a primary focus, our services extend to surrounding metro areas and industrial hubs. This regional coverage allows us to provide fast, responsive service for both scheduled maintenance and urgent repair needs, ensuring that our clients benefit from timely diagnostics and solutions wherever they are located.In addition to serving Rochester Hills, we provide vibration analysis and related services to nearby metro communities and industrial hubs. This allows us to respond quickly to both scheduled service requests and urgent maintenance needs, ensuring that businesses in the surrounding areas benefit from our expertise and fast response times.

Why Vibration Analysis is Essential for Southfield’s Industrial Sector

Southfield’s industrial sector demands efficiency, precision, and reliability. Vibration analysis plays a vital role in meeting these demands by enabling maintenance teams to identify and correct issues during planned service intervals rather than reacting to emergencies. This proactive strategy reduces repair costs, enhances asset performance management, and extends equipment lifespan. Continuous machine health monitoring improves workplace safety, ensures consistent production quality, and supports compliance with industry regulations. In a competitive marketplace, vibration analysis gives Southfield businesses the control and insight needed to maintain operational excellence.

Frequently Asked Questions (FAQs)

What equipment do you use for vibration analysis?

We use advanced diagnostic equipment from leading brands, including Brüel & Kjær, SKF, Fluke, Bentley Nevada, and Emerson AMS. Our toolkit includes high-precision vibration sensors, portable balancing machines, and sophisticated analysis software to deliver highly accurate results.

How often should vibration analysis be performed?

The ideal frequency depends on equipment usage, criticality, and operating conditions. High-priority machinery often requires quarterly or semiannual testing, while less critical equipment may be monitored annually. We customize maintenance schedules to fit each client’s operational requirements.

Can vibration analysis prevent all mechanical failures?

While vibration analysis cannot eliminate every potential failure, it is one of the most effective methods for early fault detection. By catching issues early, it greatly reduces the risk of unplanned breakdowns and helps ensure planned maintenance is more effective.

Do you offer on-site balancing services in Southfield?

Yes, we provide full on-site industrial field balancing services across Southfield and the surrounding areas. This allows us to correct imbalances without removing machinery from service, minimizing downtime and costs.

What industries benefit the most from vibration analysis?

Industries such as automotive manufacturing, aerospace engineering, steel production, food processing, textiles, and power generation benefit greatly from regular vibration monitoring. These sectors depend heavily on rotating equipment, making preventive maintenance critical for reliability and efficiency.

Get Started with Professional Vibration Analysis in Southfield, MI

If you’re ready to improve your machinery’s performance and protect your production schedules, Dynamic Balancing Technologies is here to help. We offer free consultations to evaluate your needs and develop a customized vibration analysis plan that works within your operational framework. With flexible scheduling and 24/7 emergency on-site services, we ensure expert support is always available when you need it. Serving Southfield and the entire Michigan industrial market, we deliver accurate diagnostics, targeted solutions, and the confidence that comes from working with experienced professionals. Contact us today to schedule your vibration analysis and keep your equipment performing at its peak.