At Dynamic Balancing Technologies, we recognize the crucial role that dynamic balancing plays in the success of industrial operations throughout Detroit. Whether you’re running a high-output manufacturing plant or a specialized aerospace machining facility, the performance and longevity of your rotating machinery depend on its ability to function with minimal vibration. Our expertise in dynamic balancing for industrial applications in Detroit enables our clients to experience smoother operations, fewer mechanical failures, and significantly lower maintenance costs. When it comes to balancing heavy-duty equipment in high-demand environments, our precision methods offer measurable benefits.

The Importance of Dynamic Balancing in Industrial Applications

Dynamic balancing is not just a maintenance task—it is a foundational aspect of industrial machinery health. Industrial equipment such as pumps, fans, motors, impellers, spindles, and blowers all rely on rotational motion. If there is any mass distribution error, even a minor one, the imbalance creates a centrifugal force that translates into unwanted vibration. This vibration can lead to accelerated wear on components like bearings, couplings, and seals. In many cases, prolonged exposure to vibration causes these parts to fail prematurely, leading to production downtime and costly repairs.

In Detroit’s competitive industrial sector, efficiency, reliability, and uptime are non-negotiable. Our dynamic balancing solutions are crafted to support these priorities. We reduce vibration to acceptable tolerance levels, minimize operational noise, and help your machines perform better for longer. By partnering with our experienced team, industrial clients across Michigan and the Midwest enjoy not only performance improvement but also improved safety and compliance.

Why Industrial Equipment Fails Without Proper Balancing

Imbalance is often an invisible enemy in industrial settings. While it may start with a barely noticeable increase in vibration, it quickly escalates into a cascade of mechanical issues. Rotating components experience uneven wear patterns that compromise their structural integrity. As the imbalance persists, the connected machinery also begins to suffer from misalignment and increased friction. Ultimately, this can lead to breakdowns, production delays, or even hazardous working conditions.

Dynamic balancing technologies address this issue at its root. By realigning the mass centerline of a rotating component to its axis of rotation, we eliminate the forces that lead to vibration. The outcome is a machine that runs smoothly, with reduced mechanical stress and improved performance. Our clients in Detroit rely on this preventive measure to protect their equipment investments, extend machine lifespan, and avoid emergency service calls that could have been prevented with routine balancing.

Meet Detroit’s Trusted Partner – Dynamic Balancing Technologies

With over 32 years of experience and a reputation for technical excellence, Dynamic Balancing Technologies has established itself as a trusted resource for companies seeking dynamic balancing in Detroit. We’re headquartered in Romeo, MI, and our services reach industrial clients across Michigan, Indiana, Ohio, Illinois, and beyond. We combine our background in mechanical engineering with hands-on field service experience to deliver reliable, results-driven solutions.

As a certified provider categorized under mechanical engineering, machine shops, industrial equipment suppliers, and maintenance services, we serve a broad spectrum of industries. Whether you operate in the automotive, aerospace, food processing, energy generation, or chemical manufacturing industries, we understand the standards, expectations, and equipment that define your sector. Our facility features state-of-the-art balancing machines capable of handling components up to 250 pounds, and our mobile teams are fully equipped to balance machinery on-site with the same level of precision.

In-Shop Dynamic Balancing for Rotating Components

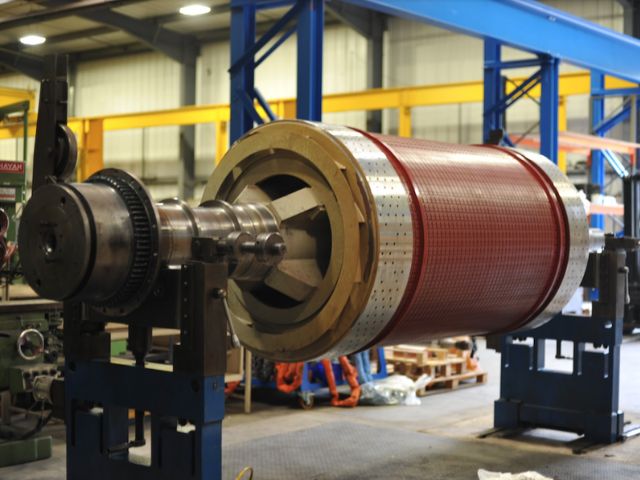

Our in-shop dynamic balancing services are ideal for components that can be removed and transported. We offer balancing for rotors, fans, impellers, electric motors, and other precision components. Each balancing job starts with a vibration analysis, where we evaluate the component’s behavior during rotation. Using calibrated machines and software aligned with ISO 1940 standards, we determine the correct corrections needed to reduce vibration.

Our team then applies weight removal or addition techniques across single or dual planes to achieve a near-zero imbalance. After rebalancing, we verify our results through repeat diagnostics, providing you with before-and-after reports that show measurable improvements. Many of our Detroit clients rely on this service as part of their annual or semi-annual preventive maintenance plans.

On-Site Field Balancing Services for Detroit’s Industrial Facilities

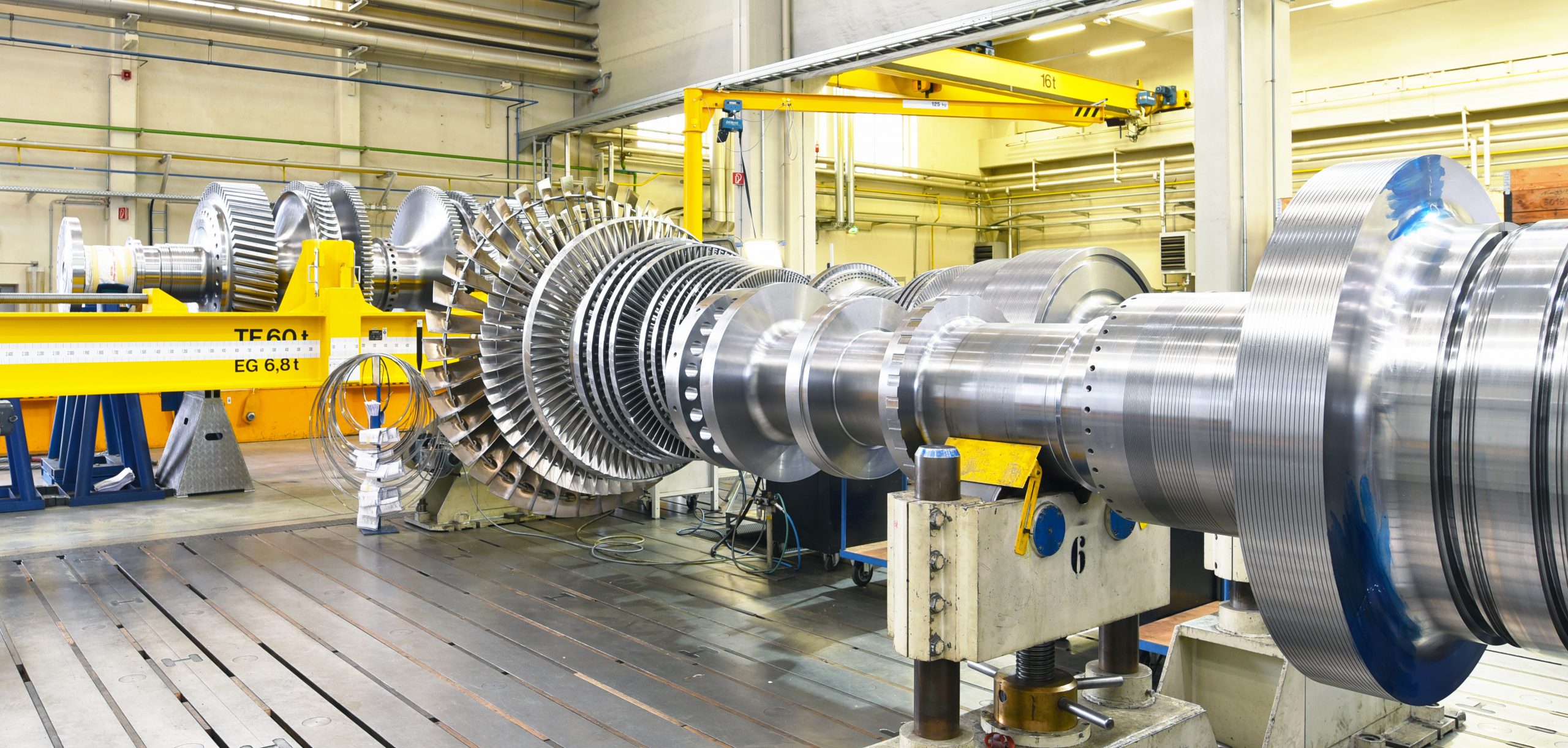

For equipment that is too large or too integrated into a system to be transported, we offer comprehensive on-site field balancing services. Our portable balancing instruments and diagnostic tools allow us to perform precise balancing corrections without removing the component from service. This service is particularly useful for HVAC blowers, turbines, pumps, and installed motors in manufacturing plants, hospitals, and energy facilities.

Our mobile balancing units are deployed across the Detroit area and are supported by experienced field engineers who understand the unique demands of your industrial environment. With minimal disruption to your operations, we correct imbalance conditions, reduce vibration, and verify performance on-site. This helps clients avoid costly disassembly, shipping, and extended equipment downtime.

Static Balancing Solutions for Low-Speed Industrial Equipment

Static balancing is an equally important service for low-speed or stationary equipment. In applications such as heavy wheels, pulleys, or slow-turning shafts, the imbalance may not be noticeable until it causes wear, noise, or instability. In these situations, we perform static balancing, which involves correcting the uneven mass distribution across a single plane.

By ensuring that the center of gravity aligns with the axis of rotation, we eliminate heavy spots that could otherwise lead to rolling or inconsistent load transfer. Static balancing is particularly important in backup systems, emergency equipment, and components that don’t experience dynamic forces but must remain in perfect mechanical alignment. We offer static balancing services, both in-shop and on-site, tailored to your specific needs.

Vibration Analysis as a Foundation for Balancing Accuracy

We believe that accurate balancing starts with a complete understanding of your equipment’s vibration profile. That’s why every dynamic balancing job we undertake includes a vibration analysis component. Our team uses high-resolution sensors and software to measure velocity, acceleration, and frequency spectrum. This helps us identify whether vibration is caused by imbalance, misalignment, mechanical looseness, or other structural issues.

For many of our Detroit clients, vibration analysis is a standard part of their predictive maintenance program. By routinely analyzing their equipment, they can identify potential problems early and schedule maintenance proactively. Our reports are designed to be informative and actionable, allowing plant managers and maintenance supervisors to make informed decisions about their machinery.

Laser Shaft Alignment for High-Performance Industrial Systems

In addition to dynamic and static balancing, we offer advanced laser shaft alignment services to protect your interconnected machinery. Shaft misalignment is a leading cause of vibration and equipment failure in rotating systems. It places stress on bearings, accelerates seal degradation, and increases power consumption. Our laser alignment tools help us detect and correct even the most minor deviations in shaft position.

We work with a wide range of equipment including pumps, gearboxes, compressors, and motors. Once properly aligned, these machines run more smoothly, experience less friction, and maintain efficiency over a longer period. Laser alignment is a crucial component of our comprehensive machinery health offering and is often combined with balancing services for optimal results.

Balancing Services for Industrial Fans, Motors, and Blowers

Fans, blowers, and motors are essential components in many industrial processes and facility operations. They are also among the most vibration-sensitive pieces of equipment. At Dynamic Balancing Technologies, we provide specialized balancing services to restore these units to optimal performance. Whether you’re dealing with HVAC systems, exhaust fans, or process blowers, we ensure that each component operates with minimal vibration and maximum efficiency.

Our team analyzes factors such as airflow irregularities, noise levels, and motor heating to diagnose issues related to imbalance. After applying the necessary corrections, we verify results using post-balancing vibration analysis. Detroit facilities that rely on consistent air movement and energy efficiency turn to us to ensure their fan systems are always in peak condition.

CNC and Spindle Tooling Balancing for Manufacturing Efficiency

Precision manufacturing environments such as CNC machining centers, aerospace tool shops, and automotive production lines depend on spindle tooling that performs with micron-level accuracy. An unbalanced spindle can cause chatter, tool wear, dimensional inaccuracies, and surface defects. Our spindle and tooling balancing services are designed to meet the high-performance standards of Detroit’s manufacturing industry.

We balance spindle assemblies, tool holders, and rotating components used in CNC applications. Our process reduces tool runout, improves surface finishes, and extends tooling life. This is especially valuable for industries where tight tolerances and high-speed rotation are the norm. We understand the high-stakes nature of your production goals and provide balancing solutions that match those expectations.

Industries in Detroit That Rely on Dynamic Balancing

Our clients span a wide range of sectors, each with its machinery requirements and vibration thresholds. In the automotive industry, we balance components for assembly lines, robotic arms, and electric motor systems. Aerospace manufacturers rely on us to balance critical components, such as turbine blades, jet engine parts, and precision tooling.

We also support energy utilities by balancing rotating equipment used in power generation and distribution. Food and pharmaceutical processors rely on us for fan, pump, and blower balancing, which ensures clean and uninterrupted operation. Paper mills, chemical plants, and HVAC service providers throughout Detroit trust our expertise to keep their equipment running with minimal disruption.

Benefits of Choosing Dynamic Balancing Technologies

Choosing our team means choosing reliability, accuracy, and long-term savings. We help Detroit businesses reduce emergency breakdowns, avoid downtime, and enhance the lifespan of their equipment. Our services are competitively priced and backed by detailed diagnostics, actionable insights, and a commitment to continuous improvement.

We’re not just another balancing provider. We act as a partner to your maintenance team, offering recommendations that align with your goals for efficiency, safety, and compliance. Every balancing job is thoroughly documented with before-and-after results, providing clear evidence of performance improvement and return on investment.

Frequently Asked Questions (FAQ)

How does dynamic balancing improve industrial productivity?

Dynamic balancing reduces vibration, resulting in smoother machine operation, reduced wear on components, and improved reliability. This translates to fewer interruptions and more efficient output.

Can you perform balancing for non-removable equipment?

Yes, we provide on-site field balancing services for equipment that is fixed in place. Our mobile teams are equipped to handle diagnostics and corrections on location.

What types of rotating parts can you balance?

We balance rotors, fans, impellers, shafts, blowers, spindles, motors, and more. If it rotates, we can balance it.

How often should vibration analysis be performed?

For critical systems, we recommend conducting quarterly or semiannual vibration analyses. Less critical systems may be tested annually, depending on usage and wear patterns.

Why is shaft alignment important in high-performance systems?

Shaft misalignment leads to increased wear, higher energy consumption, and premature failure of components such as seals and bearings. Laser shaft alignment ensures precise positioning and long-term efficiency.

Contact Dynamic Balancing Technologies for Industrial Services in Detroit

If your industrial operation depends on rotating machinery, don’t wait for an imbalance to cause a failure. At Dynamic Balancing Technologies, we offer Detroit’s most comprehensive and affordable dynamic balancing services. From vibration diagnostics to spindle balancing, we’re ready to support your equipment and help your business thrive.

Address: 295 North Main Street, Romeo, MI 48065

Phone: (586) 280-8256

Email: dynamicbalancingtech@gmail.com